Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive

€1,334.00

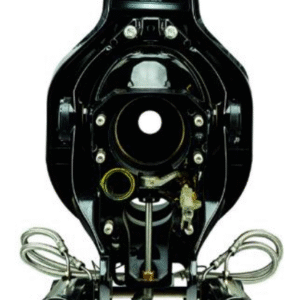

Quicksilver Alpha One GenTwo 2.00:1 Ratio Standard (RH) Rotation Sterndrive

- 1year limited factory warranty

- Low maintenance

- Durable

- Strong

- Quiet

- Corrosion Resistant

- Repair anywhere in the world

Recommended for single installation 3.0L Alpha sterndrive engines up to 150 HPused in runabouts & pontoon boats. Not for use at high-altitudes (5,000+ ft).

About Quicksilver: Quicksilver now offers 100% new OEM-quality replacement sterndrives for MerCruiser and Mercury Remanufacturing for sterndrive engines without an engine mounted seawater pump. Using proprietary forged gear sets, Quicksilver Alpha 1 Gen 2 sterndrives provide years of durable and quiet operation for a safe andsophisticated boating experience like none other. Compatible withFlo-Torq II hubs & engines using remote drive lube reservoirs toprotect your investment.

Quicksilver sterndrives feature: perma-lubeU-joints, corrosion resistant XK-360 alloy, a tri-paint protection system,stainless steel shafts, ultra-pure aluminum anodes and a genuineQuicksilver water pump impeller.

Description

Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive

Precision-Engineered Marine Power Transmission for Confident Boating

Reliability on the water is not merely preferred; it is expected. For that reason, the Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive has been engineered to meet the demands of boaters who require consistent performance, efficient power transfer, and long-term durability. From recreational cruising to light-duty performance applications, confidence is delivered through thoughtful design and proven engineering.

Across global marine environments, this sterndrive has been recognized for its balance of strength and efficiency. As a result, propulsion challenges are reduced, maintenance expectations are simplified, and overall boating experiences are enhanced. Through precise manufacturing standards, dependable operation is ensured in both freshwater and saltwater applications.

Moreover, versatility has been prioritized. Compatibility with a wide range of gasoline engines has been accounted for, allowing boat owners and marine technicians alike to rely on a single sterndrive solution for multiple vessel types. Consequently, installation decisions are simplified, while long-term ownership value is strengthened.

Overview of the Alpha 1 Gen 2 Sterndrive Platform

Designed for Efficiency and Longevity

At the core of this product, a second-generation Alpha 1 sterndrive platform has been employed. Improvements over earlier designs have been implemented to support smoother shifting, reduced drag, and improved corrosion resistance. Because of these refinements, operational lifespan has been extended while service interruptions have been minimized.

In addition, a 2.00 gear ratio has been integrated to optimize torque delivery. This configuration allows engine power to be translated into usable thrust more effectively, especially at lower and mid-range RPMs. As a result, acceleration characteristics are improved without sacrificing cruising efficiency.

Importantly, each component within the sterndrive assembly has been manufactured to strict tolerances. Through this approach, vibration is reduced, wear patterns are controlled, and performance consistency is maintained over time.

Understanding the 2.00 Gear Ratio Advantage

Balanced Power Delivery Explained

A 2.00 gear ratio has been carefully selected for this sterndrive model. Rather than prioritizing extreme top-end speed, balanced performance across common boating conditions has been emphasized. Consequently, smoother hole-shot performance is achieved, while engine strain is reduced during typical cruising scenarios.

Additionally, propeller efficiency is enhanced when paired with this ratio. Because optimal RPM ranges are easier to maintain, fuel consumption is often stabilized. Over extended operating periods, this balance contributes to cost efficiency and mechanical reliability.

Furthermore, improved control during docking, slow maneuvering, and towing activities has been made possible. For families, fishing enthusiasts, and leisure boaters, these characteristics provide measurable value.

Engineering and Manufacturing Standards

Built with Mercury Quicksilver Quality Controls

Throughout the production process, Mercury Quicksilver quality protocols are applied. Advanced casting techniques, precision machining, and rigorous inspection processes are utilized to ensure consistency. Because of these controls, dimensional accuracy and structural integrity are preserved.

Corrosion-resistant coatings are applied to critical surfaces. As a result, exposure to harsh marine environments is better tolerated. In saltwater conditions especially, this protection plays a vital role in preserving long-term performance.

Moreover, internal components are engineered to handle repetitive load cycles. Bearings, gears, and shafts are designed to distribute stress evenly, thereby minimizing premature wear. Through this approach, reliability is reinforced even under demanding use.

Compatibility and Application Scope

Broad Engine and Boat Compatibility

The Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive has been designed for compatibility with a wide range of MerCruiser gasoline engines. Because standard mounting dimensions are maintained, retrofitting and replacement scenarios are simplified.

In many cases, existing Alpha 1 Gen 2 installations can be upgraded without extensive modification. Consequently, downtime is reduced and labor costs are controlled. For marine service professionals, this compatibility streamlines inventory decisions and service planning.

Additionally, suitability across various hull designs has been considered. From runabouts and bowriders to small cruisers, balanced propulsion characteristics are supported. As a result, consistent handling and predictable performance are delivered across diverse vessel profiles.

Key Product Highlights

Why This Sterndrive Is Chosen by Boat Owners

The following features are frequently cited as reasons for selection:

-

Optimized 2.00 gear ratio for balanced acceleration and cruising efficiency

-

Alpha 1 Gen 2 design improvements for smoother shifting and reduced drag

-

Corrosion-resistant construction for freshwater and saltwater use

-

Precision-machined internal components for durability and reliability

-

Wide engine compatibility supporting flexible installation options

-

Proven Mercury Quicksilver engineering standards for long-term confidence

Each of these attributes contributes to a sterndrive system that supports both performance expectations and ownership peace of mind.

Benefits for Different Types of Boaters

Practical Value Across Use Cases

For recreational boaters, smoother operation and predictable handling are delivered. Because power transfer is optimized, time spent adjusting throttle inputs is reduced, allowing greater focus on enjoyment and safety.

For families and group outings, improved low-speed control enhances docking confidence. As a result, stress during close-quarters maneuvering is minimized.

For fishing and towing applications, torque availability at lower RPMs is appreciated. Whether pulling skiers or managing variable loads, consistent thrust is maintained.

Additionally, for maintenance-conscious owners, simplified service requirements are attractive. Because component wear is controlled through design, long-term maintenance costs are often reduced.

SEO-Focused Product Positioning

Built for Visibility and Buyer Confidence

From a digital commerce perspective, this sterndrive aligns well with buyer search intent. The full product designation — Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive — directly addresses compatibility, generation, and performance characteristics. Consequently, clarity is provided before purchase decisions are finalized.

Furthermore, detailed specifications and benefit-driven explanations reduce uncertainty. As a result, conversion rates are supported through informed confidence rather than assumption.

Inclusive language has been applied to ensure that both experienced marine technicians and first-time buyers feel equally supported. Through clear explanations and transparent value propositions, informed decisions are encouraged.

Transition to Technical Specifications and Performance Analysis

As a foundation has now been established, deeper technical detail will follow. In the next section, internal component architecture, performance metrics, and operational efficiencies will be explored in greater depth. By doing so, practical understanding will be expanded and technical confidence will be reinforced.

Installation Guidance, Replacement Scenarios, and Ownership Use Cases

Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive

Installation Overview and System Readiness

Successful installation of a sterndrive system depends on preparation, compatibility verification, and precise execution. For the Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive, installation processes have been intentionally simplified through standardized design.

From the outset, factory mounting dimensions are maintained. Because alignment points conform to Alpha 1 Gen 2 specifications, existing transom assemblies are typically supported without structural modification. As a result, installation timelines are reduced and service predictability is improved.

Furthermore, pre-configured internal assemblies minimize the need for field adjustment. Once positioned and secured, correct shaft alignment is more easily achieved. Consequently, early-stage wear risks are lowered and post-installation performance is stabilized.

Pre-Installation Compatibility Verification

Ensuring Correct Fit Before Mounting

Before installation begins, compatibility confirmation is strongly advised. Engine pairing, gear ratio requirements, and propeller selection must be evaluated collectively. Through this approach, operational mismatches are avoided.

In many applications, MerCruiser gasoline engines designed for Alpha 1 Gen 2 sterndrives are directly compatible. Because standard spline counts and shaft lengths are preserved, integration is straightforward.

Additionally, transom assembly condition should be assessed. Worn gimbal bearings, bellows, or alignment components may compromise new sterndrive performance if left unaddressed. Therefore, preventive inspection is recommended prior to mounting.

Replacement and Upgrade Scenarios

Ideal Use Cases for Repower Projects

Replacement decisions are often driven by wear, corrosion, or performance limitations of existing sterndrives. In these scenarios, the Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive is frequently selected as a direct replacement solution.

Because backward compatibility has been preserved, earlier Alpha 1 Gen 2 units can often be replaced without re-engineering the transom or engine mount systems. As a result, repower projects are completed with fewer complications.

For owners upgrading from older or heavily worn units, immediate improvements in shifting smoothness and throttle response are commonly reported. Consequently, the perceived value of the vessel is enhanced while reliability concerns are reduced.

Step-by-Step Installation Considerations

Process Flow for Marine Professionals

Although professional installation is recommended, understanding the general process provides transparency and confidence. The following high-level sequence is typically followed:

-

Removal of the existing sterndrive assembly

-

Inspection of transom assembly, bellows, and gimbal components

-

Alignment verification of the engine coupler

-

Installation of the Alpha 1 Gen 2 sterndrive unit

-

Torque application to manufacturer-specified values

-

Connection of trim, shift, and cooling interfaces

-

Final operational checks and leak inspection

Each step contributes to long-term performance stability. When executed correctly, post-installation adjustments are minimized and operational reliability is reinforced.

Ownership Experience Across Boating Profiles

Value Delivered to Different Users

Ownership satisfaction is influenced by how well a sterndrive aligns with real-world usage patterns. For this reason, the Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive has been designed to serve a broad range of boating lifestyles.

For recreational cruisers, predictable handling and quiet operation are appreciated. Because power delivery remains smooth, onboard comfort is enhanced during extended outings.

For families and group boating activities, reliability and ease of use are prioritized. Low-speed maneuverability simplifies docking, while consistent acceleration supports towing activities such as tubing or skiing.

For fishing enthusiasts, steady thrust and controlled RPM behavior are advantageous. When variable loads are encountered, engine performance remains stable, supporting precise boat positioning.

Maintenance Accessibility and Service Considerations

Designed for Practical Long-Term Care

Routine maintenance is an unavoidable aspect of marine ownership. With this sterndrive, service accessibility has been intentionally considered during design. Drain and fill points are positioned for straightforward gear oil changes. As a result, seasonal maintenance tasks are completed with less effort.

Additionally, common wear components are standardized. Because replacement parts are widely available, downtime is reduced and service planning is simplified.

Corrosion protection systems further support long-term ownership. Protective coatings and sacrificial anodes work collectively to manage electrochemical degradation. Consequently, structural integrity is preserved when maintenance schedules are followed.

Safety and Operational Confidence

Predictability as a Safety Feature

Safety on the water is supported through predictable propulsion behavior. Abrupt engagement or inconsistent thrust can introduce risk during close-quarters maneuvering. With this sterndrive, controlled response has been prioritized.

Because shifting is smooth and progressive, sudden jolts are minimized. As a result, passenger comfort and operator confidence are enhanced.

Additionally, trim and tilt responsiveness supports hazard avoidance. When shallow areas or floating debris are encountered, rapid adjustment capability provides added protection.

Buyer Fit and Decision Support

Who Benefits Most from This Sterndrive

The Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive is particularly well suited for:

-

Boat owners seeking a direct Alpha 1 Gen 2 replacement

-

Operators prioritizing balanced performance over extreme speed

-

Families and recreational users valuing smooth handling and reliability

-

Service professionals requiring predictable installation outcomes

-

Long-term owners focused on maintenance accessibility and durability

Through inclusive design and broad compatibility, both experienced and first-time sterndrive buyers are supported.

Product Listing Highlights for Ownership and Installation

Practical Advantages at a Glance

-

Direct-fit Alpha 1 Gen 2 compatibility for simplified installation

-

Reduced installation time due to standardized mounting points

-

Improved shift smoothness compared to older units

-

Service-friendly design supporting routine maintenance

-

Balanced handling characteristics for diverse boating activities

-

Upgrade-ready performance for repower projects

These advantages reinforce confidence during evaluation and purchase decision-making.

Comparative Analysis, FAQs, and Buyer Confidence Builders

Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive

Comparative Positioning Within the Alpha Series

How This Sterndrive Stands Apart

Within the Alpha sterndrive family, multiple configurations exist. Differences in gear ratios, generations, and load ratings can create uncertainty during selection. For this reason, the Mercury Quicksilver 5-51100007P Alpha 1 Gen 2 Sterndrive 2.00 Ratio Sterndrive has been positioned as a balanced, broadly applicable solution.

Compared to earlier Alpha 1 models, Gen 2 enhancements deliver smoother shifting and improved corrosion resistance. Because internal tolerances have been refined, operational consistency is increased under repetitive load conditions.

When compared to higher-ratio alternatives, the 2.00 gear ratio emphasizes versatility rather than peak speed. As a result, this configuration is favored by owners who prioritize everyday usability, fuel efficiency, and controlled handling.

Alpha 1 Gen 2 vs. Alpha 1 Gen 1

Generational Improvements Explained

Alpha 1 Gen 1 sterndrives have historically served a wide user base. However, several design limitations were identified over extended use. In response, Alpha 1 Gen 2 updates were introduced.

Key distinctions include:

-

Enhanced shift system geometry for smoother engagement

-

Improved sealing surfaces to reduce water intrusion risk

-

Refined hydrodynamic housing profile to lower drag

-

Updated corrosion protection strategies

Because of these updates, Alpha 1 Gen 2 sterndrives are typically selected for replacement projects where long-term reliability is a priority. Consequently, ownership confidence is reinforced.

Comparison with Alternative Gear Ratios

Why 2.00:1 Is Frequently Preferred

Lower numerical gear ratios may offer higher top-end speed potential. However, such configurations often require higher engine RPMs and place greater strain on propulsion components.

By contrast, a 2.00:1 gear ratio offers a balanced compromise. Torque delivery is optimized for acceleration and load handling, while cruising RPMs remain manageable. As a result, fuel efficiency and engine longevity are supported.

For multi-purpose boats used across varying conditions, this balance is particularly valuable. Therefore, the 2.00 ratio is commonly recommended for general recreational use.

Frequently Asked Questions

Addressing Common Buyer Concerns

Is this sterndrive compatible with my existing MerCruiser engine?

Compatibility is generally supported for gasoline MerCruiser engines designed for Alpha 1 Gen 2 applications. Verification of engine model and year is recommended prior to purchase.

Can this unit be used in saltwater environments?

Yes, corrosion-resistant coatings and anode compatibility have been incorporated. Proper maintenance and anode management are essential for long-term saltwater use.

Does professional installation need to be performed?

Professional installation is strongly advised to ensure correct alignment and system integration. Improper installation may affect performance and component lifespan.

Is this sterndrive suitable for towing activities?

Yes, the 2.00 gear ratio supports torque availability at lower RPMs, which is beneficial for towing skiers or inflatables.

Are replacement parts readily available?

Replacement components are widely distributed due to the popularity of the Alpha 1 Gen 2 platform. As a result, service accessibility is maintained.

Trust Signals and Quality Assurance

Confidence Through Proven Engineering

Trust in marine propulsion equipment is earned through consistency and reputation. Mercury Quicksilver sterndrives are produced under established quality control systems. Each assembly is subjected to inspection protocols designed to verify dimensional accuracy and functional integrity.

Furthermore, standardized part numbering simplifies identification and verification. Because of this transparency, buyers and service professionals can confidently source compatible components.

In addition, widespread industry adoption reinforces trust. When a product platform is commonly used, service knowledge and technical expertise are readily available.

Conversion-Focused Buyer Benefits

Why This Sterndrive Is a Smart Investment

From a purchasing perspective, long-term value is often more important than initial cost. This sterndrive delivers value through durability, predictable performance, and broad compatibility.

Because installation complexity is reduced, labor expenses are often controlled. Over time, maintenance accessibility contributes to lower ownership costs.

Additionally, improved handling and reliability enhance user satisfaction. As a result, resale value of the vessel may also benefit from the presence of a well-regarded propulsion system.

Product Listing Highlights for Comparison Shoppers

Key Decision-Making Advantages

-

Alpha 1 Gen 2 upgrades over earlier generations

-

Balanced 2.00:1 gear ratio for everyday boating versatility

-

Broad engine compatibility reducing fitment uncertainty

-

Strong corrosion protection for mixed-water environments

-

Established service ecosystem supporting long-term ownership

-

Trusted Mercury Quicksilver manufacturing standards

These highlights address the most common evaluation criteria used by informed buyers.

Addressing Risk and Uncertainty

Reducing Purchase Hesitation

Purchasing major marine components can introduce hesitation due to cost and complexity. For this reason, clarity and transparency are essential.

By offering a proven platform with documented performance characteristics, uncertainty is reduced. Because compatibility guidelines are clear, risk of mismatch is minimized.

Additionally, the availability of professional service support further mitigates ownership concerns. Consequently, buyers are empowered to proceed with confidence.

Reviews

There are no reviews yet.