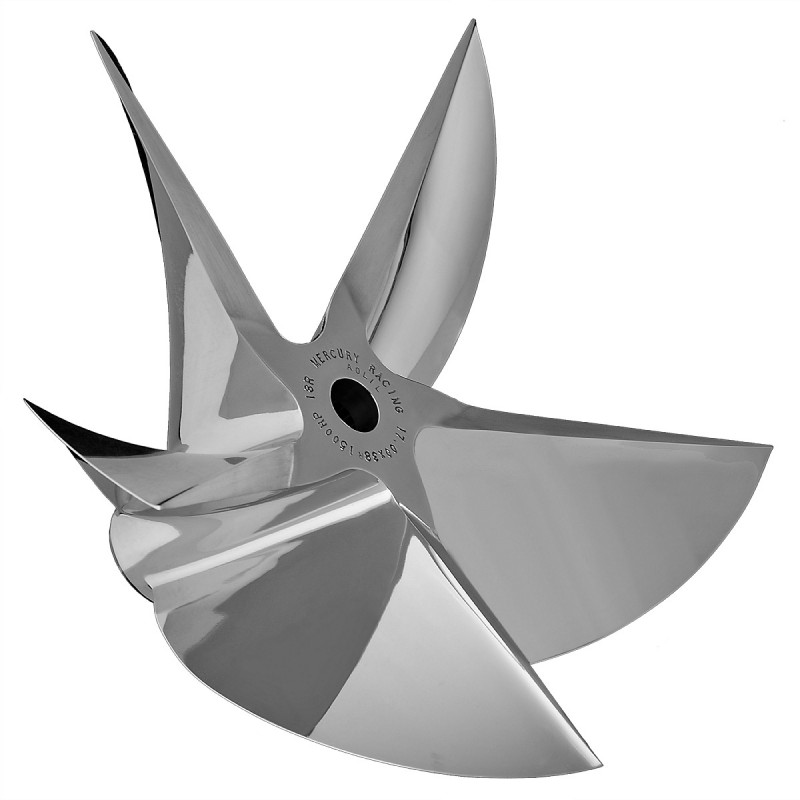

Mercury Racing CNC Cleaver Pro Finished 5 blade Sterndrive Propeller

€5,170.00

Description

Mercury Racing CNC Cleaver Pro Finished 5 Blade Sterndrive Propeller

Performance on the water is not achieved by chance. It is engineered through precision, validated through testing, and experienced through control. The Mercury Racing CNC Cleaver Pro Finished 5 Blade Sterndrive Propeller has been developed for boaters who expect measurable results rather than marketing promises. Every design decision reflects a singular objective: converting engine power into efficient, stable, and repeatable propulsion at speed.Mercury Racing CNC Cleaver

Backed by the engineering heritage of Mercury Racing, this propeller is positioned at the intersection of advanced manufacturing and real-world marine performance. High-output sterndrive systems demand accuracy at the blade level, consistency across production, and durability under load. Those requirements are addressed through CNC machining, a refined cleaver profile, and a professionally finished surface that reduces hydrodynamic resistance.

Rather than serving as a generic replacement component, this propeller functions as a performance upgrade. Speed, handling, and responsiveness are improved simultaneously, ensuring that no single performance metric is enhanced at the expense of another.Mercury Racing CNC Cleaver

Designed for Precision-Driven Marine Performance

Marine propulsion efficiency is influenced by blade geometry, balance, surface finish, and load distribution. Each of these variables has been optimized within this propeller to deliver predictable results across a wide range of operating conditions.Mercury Racing CNC Cleaver

CNC Machining for Exacting Tolerances

Computer Numerical Control (CNC) machining ensures that each blade is cut to precise specifications. Variability associated with casting or manual finishing processes is eliminated. As a result, blade pitch, rake, and cup remain consistent from unit to unit.

This level of precision produces tangible advantages:

-

Hydrodynamic efficiency is improved

-

Harmonic vibration is reduced

-

Engine-to-propeller power transfer becomes more efficient

Because tighter tolerances are maintained, performance remains consistent even during sustained high-speed operation.Mercury Racing CNC Cleaver

Five-Blade Cleaver Geometry Explained

The cleaver-style blade profile has long been associated with high-speed sterndrive and surface-piercing applications. In this configuration, thrust is optimized at elevated RPM ranges while maintaining directional stability.

Why a Five-Blade Configuration Matters

Increasing blade count alters how torque is distributed through the water. With five blades engaged, thrust loads are spread more evenly. This design choice enhances grip, particularly during aggressive acceleration and high-speed cornering.Mercury Racing CNC Cleaver

Operational benefits include:

-

Faster planing characteristics

-

Improved mid-range control

-

Enhanced stability in rough or aerated water

Instead of relying on raw engine output alone, this propeller uses blade efficiency to maintain momentum and control.

Pro Finished Surface for Reduced Hydrodynamic Drag

Surface finish directly impacts water flow across the blade face. Micro-imperfections create turbulence, which increases drag and reduces efficiency. This propeller is professionally finished to minimize those imperfections.Mercury Racing CNC Cleaver

Performance Impact of a Pro Finish

A smoother surface promotes cleaner water separation and more consistent pressure distribution. Consequently, top-end speed potential is increased while engine strain is reduced.Mercury Racing CNC Cleaver

Key advantages include:

-

Higher achievable speeds at wide-open throttle

-

More efficient cruising RPM ranges

-

Reduced long-term blade fatigue

The finish is not cosmetic. It is functional, contributing directly to performance outcomes.

Engineered for High-Horsepower Sterndrive Systems

High-performance sterndrives operate under significant mechanical stress. Torque spikes during acceleration and sustained RPM at speed place heavy demands on propulsion components. This propeller has been engineered to handle those conditions reliably.

Mercury Racing CNC Cleaver Ideal Application Scenarios

This propeller is particularly well-suited for:

-

Offshore performance boats

-

High-speed recreational sterndrive vessels

-

Competitive and semi-competitive marine environments

-

Boats requiring enhanced control at elevated speeds

By optimizing blade loading, drivetrain stress is managed more effectively, supporting both performance and longevity.Mercury Racing CNC Cleaver

How Hydrodynamics Shape Real-World Propeller Performance

Water is an unforgiving medium. Small inefficiencies at the blade level compound rapidly as speed increases. For this reason, the hydrodynamic profile of the Mercury Racing CNC Cleaver Pro Finished 5 Blade Sterndrive Propeller has been engineered with a performance-first mindset. Every curve, edge, and angle exists to control water flow, manage pressure differentials, and convert rotational energy into forward motion with minimal loss.

Rather than relying on generalized design assumptions, this propeller leverages proven hydrodynamic principles to ensure predictable performance across a broad RPM range. Acceleration, lift, and stability are addressed simultaneously, ensuring balanced behavior under varying load and sea conditions.Mercury Racing CNC Cleaver

Cleaver Blade Design: Managing Lift and Thrust at Speed

Cleaver-style propellers differ fundamentally from round-ear or semi-cleaver designs. Lift is generated primarily at the trailing edge rather than across the entire blade surface. This characteristic is particularly advantageous for high-speed sterndrive applications.

Trailing-Edge Lift Explained

By concentrating lift toward the rear of the blade:

-

Bow lift is reduced

-

Stern lift is increased

-

Hull attitude becomes flatter at speed

As a result, drag is minimized while directional stability is enhanced. This flatter running angle allows boats to maintain speed more efficiently, especially in offshore or choppy conditions.

Blade Geometry Optimization Through CNC Machining

Blade geometry consistency is essential when hydrodynamic balance is required. CNC machining allows pitch progression, rake angle, and blade thickness to be controlled precisely from hub to tip.

Key Geometric Elements Refined

The following elements have been carefully engineered:

-

Progressive pitch: Maintains thrust as RPM increases

-

Optimized rake: Improves water retention at high speeds

-

Balanced blade thickness: Enhances strength without adding unnecessary drag

Because these parameters remain consistent across all five blades, oscillation and imbalance are minimized. Consequently, smoother power delivery is achieved throughout the operating range.

Five-Blade Load Distribution and Torque Management

Torque management becomes increasingly important as engine output rises. With fewer blades, torque loads concentrate on limited surface area. In contrast, a five-blade configuration distributes those forces more evenly.

Hydrodynamic Benefits of Increased Blade Count

By spreading load across five blades:

-

Cavitation risk is reduced

-

Water grip remains consistent during acceleration

-

Steering torque fluctuations are minimized

This distribution improves control during rapid throttle changes, which is critical for performance boating environments.

Cavitation and Ventilation Control at High RPM

Cavitation and ventilation are common challenges in high-speed sterndrive applications. Both phenomena disrupt water flow and reduce effective thrust.

How This Propeller Mitigates Flow Disruption

Several design choices work together to control unwanted aeration:

-

Blade cupping enhances pressure retention

-

Optimized leading edges reduce flow separation

-

Surface finish minimizes micro-turbulence

Because pressure differentials remain stable across the blade surface, thrust remains consistent even during aggressive maneuvers.

Pro Finished Surface and Boundary Layer Efficiency

The interaction between blade surface and water occurs at the boundary layer. Surface roughness directly impacts how efficiently water adheres to the blade.

Boundary Layer Optimization

A professionally finished surface:

-

Delays boundary layer separation

-

Reduces parasitic drag

-

Improves thrust efficiency

Instead of allowing turbulence to disrupt water flow prematurely, the blade maintains controlled contact with the water for longer durations per rotation.

Comparative Analysis: Cleaver vs Standard Propeller Profiles

Standard recreational propellers prioritize versatility. High-performance cleaver propellers prioritize efficiency at speed. Understanding this distinction is critical when selecting a performance upgrade.

Key Performance Differences

| Attribute | Standard Propeller | CNC Cleaver 5-Blade |

|---|---|---|

| High-speed stability | Moderate | High |

| Load handling | General-purpose | Performance-optimized |

| Cavitation resistance | Variable | Enhanced |

| Acceleration under load | Adequate | Strong |

Because the cleaver design is purpose-built, gains are most noticeable in performance-oriented setups.

Hydrodynamic Efficiency Across Operating Ranges

Efficiency is not limited to top-end speed. Mid-range RPM performance affects cruising behavior, fuel consumption, and engine longevity.

Balanced Performance Outcomes

This propeller supports:

-

Efficient cruising at sustained RPM

-

Stable tracking during directional changes

-

Reduced engine stress under load

As a result, performance improvements remain usable rather than theoretical.

Inclusive Engineering for Diverse Operating Conditions

Water conditions vary widely. From calm inland waters to offshore chop, propeller behavior must remain predictable. This propeller has been designed to perform reliably across diverse environments.

Performance-oriented boating should remain accessible. Engineering decisions were made to support both experienced operators and those transitioning into higher-performance setups.

Real-World Performance Scenarios & On-Water Behavior

Translating Engineering into Measurable Performance

Engineering value is only meaningful when it delivers tangible results on the water. The Mercury Racing CNC Cleaver Pro Finished 5 Blade Sterndrive Propeller has been designed to perform consistently across real operating environments, not controlled laboratory conditions alone. Performance gains are experienced during acceleration, sustained cruising, high-speed operation, and directional control—each of which plays a critical role in overall boating confidence.

Rather than favoring a single performance metric, this propeller balances speed, control, and predictability. Consequently, operators experience improvements that feel intuitive rather than aggressive or unstable.

Acceleration and Hole-Shot Performance

Acceleration defines how quickly a vessel transitions from displacement to planing. In high-horsepower sterndrive applications, inefficient thrust delivery often results in delayed planing and excessive engine load.

How the Five-Blade Cleaver Improves Acceleration

By increasing blade engagement with the water, torque is converted into forward motion more efficiently. Thrust remains continuous throughout the acceleration cycle, minimizing slip.

Observable benefits include:

-

Faster planing times

-

Reduced bow rise during throttle application

-

Smoother power delivery under load

Because thrust is distributed evenly, engine RPM climbs more predictably, allowing operators to maintain control during aggressive acceleration.

Mid-Range Performance and Cruising Efficiency

While top speed attracts attention, most real-world operation occurs in the mid-range RPM band. Efficiency in this range affects comfort, fuel consumption, and drivetrain longevity.

Stable Cruising Characteristics

At cruising speeds, this propeller maintains consistent water grip. Blade geometry supports smooth thrust delivery, even when encountering variable water conditions.

Mid-range advantages include:

-

Reduced throttle modulation

-

Improved directional stability

-

Lower perceived vibration

As a result, longer runs feel less fatiguing for everyone on board.

High-Speed Stability and Top-End Control

At elevated speeds, minor inefficiencies become magnified. Hull balance, propeller bite, and steering response must remain aligned to avoid instability.

Confidence at Wide-Open Throttle

The cleaver profile and five-blade configuration work together to maintain stern lift while limiting excessive bow rise. This flatter running attitude enhances stability and reduces aerodynamic drag.

Performance outcomes include:

-

Predictable steering response

-

Reduced chine walk tendencies

-

Improved tracking in uneven water

Instead of feeling light or unsettled, the vessel remains planted and responsive as speed increases.

Cornering and Directional Control

High-speed turns place significant lateral loads on propulsion systems. Loss of grip during cornering often leads to ventilation or sudden RPM spikes.

Enhanced Grip Through Load Distribution

With five blades engaged, water contact is maintained throughout directional changes. Load transfer remains controlled, allowing the propeller to retain bite even during aggressive maneuvers.

Cornering benefits include:

-

Consistent RPM during turns

-

Reduced propeller slip

-

Improved helm feedback

These characteristics support confident handling in performance-oriented driving scenarios.

Rough-Water and Variable Condition Performance

Water conditions are rarely uniform. Chop, wake interference, and aerated water challenge propulsion efficiency.

Maintaining Thrust in Challenging Conditions

Blade cupping, optimized rake, and surface finish help manage disrupted water flow. As a result, thrust consistency is preserved even when water quality changes rapidly.

Operators commonly experience:

-

Fewer ventilation events

-

Improved throttle response in chop

-

Greater control when crossing wakes

This predictability supports safer operation when conditions become less than ideal.

Performance Across Common Use Cases

This propeller has been engineered to support a wide range of performance-focused boating activities without requiring constant setup adjustments.

Typical Application Scenarios

-

Offshore recreational performance boating

-

High-speed cruising with passengers

-

Competitive or semi-competitive environments

-

Boats requiring enhanced control at elevated speeds

Because behavior remains consistent, operators spend less time compensating for propulsion limitations and more time enjoying performance.

Comparative Performance Expectations

When transitioning from a standard recreational propeller, improvements are noticeable immediately. Gains are most pronounced in acceleration, mid-range control, and high-speed stability rather than isolated top-speed numbers alone.

What Changes First

-

Throttle response becomes more immediate

-

Steering inputs feel more connected

-

Hull attitude stabilizes earlier

These improvements contribute to a more refined overall driving experience.

Inclusive Performance for Skill Progression

Performance upgrades should support growth rather than introduce unnecessary complexity. This propeller delivers advanced performance characteristics while remaining approachable for operators refining their skills.

Predictable behavior allows confidence to build progressively. As experience increases, performance potential can be explored safely and effectively.

Materials, Durability & Long-Term Reliability

Built to Endure High-Performance Demands

Performance gains are only valuable when they can be sustained over time. High-output sterndrive systems generate continuous mechanical stress, thermal load, and hydrodynamic force. The Mercury Racing CNC Cleaver Pro Finished 5 Blade Sterndrive Propeller has been engineered to withstand these demands without degradation in performance or safety.

Rather than prioritizing lightweight construction at the expense of strength, material selection and structural design have been carefully balanced. As a result, durability is achieved without compromising hydrodynamic efficiency.

Marine-Grade Material Selection

Propeller material plays a decisive role in strength, fatigue resistance, and corrosion protection. This propeller is manufactured from premium marine-grade alloys selected for high tensile strength and resilience in aggressive marine environments.

Why Material Quality Matters

Inferior materials deform under load, leading to performance loss and vibration. In contrast, high-grade alloys maintain blade geometry even under sustained high RPM and torque.Mercury Racing

Material-related benefits include:

-

Resistance to blade flex under load

-

Long-term dimensional stability

-

Consistent performance over extended use

Because blade shape remains intact, hydrodynamic efficiency is preserved throughout the product’s lifespan.

Mercury Racing Structural Integrity Under Load

High-performance sterndrive applications place repeated cyclical stress on propulsion components. Fatigue resistance becomes critical as operating hours accumulate.Mercury Racing

Load Distribution and Structural Design

The five-blade configuration reduces peak stress concentrations by spreading load more evenly across the propeller. Blade thickness and hub reinforcement have been optimized to handle both acceleration forces and sustained cruising loads.Sterndrive Propeller

Structural advantages include:

-

Reduced risk of stress cracking

-

Improved resistance to impact-related deformation

-

Enhanced safety margins at high speed

Instead of relying on excessive mass, strength is achieved through intelligent engineering.5 blade Sterndrive Propeller

Corrosion Resistance in Marine Environments

Saltwater exposure, temperature variation, and electrochemical reactions can accelerate corrosion if not properly managed. This propeller incorporates corrosion-resistant materials and finishing processes designed for long-term exposure.Sterndrive Propeller

Protective Characteristics

-

Marine-grade alloy composition resists oxidation

-

Pro finished surface limits surface pitting

-

Reduced micro-crevices minimize corrosion initiation points

Because surface integrity is maintained, both appearance and performance are preserved over time.5 blade Sterndrive Propeller

Pro Finished Surface and Wear Reduction

Surface finish influences more than hydrodynamics. Wear resistance and ease of maintenance are also affected.

Long-Term Benefits of a Refined Finish

A smoother blade surface:

-

Resists fouling and buildup

-

Simplifies cleaning and inspection

-

Reduces abrasive wear from suspended particles

As a result, routine maintenance becomes less time-consuming, and performance consistency is easier to maintain.

Thermal Stability at High RPM

Sustained high-speed operation generates heat through friction and water interaction. Material stability under thermal variation is essential to avoid distortion.

Thermal Performance Considerations

The alloys used in this propeller maintain structural integrity across a wide operating temperature range. Consequently, blade geometry remains stable even during prolonged wide-open throttle operation.

Thermal stability supports:

-

Reliable high-speed operation

-

Reduced material fatigue

-

Consistent thrust output

Sterndrive Propeller Maintenance Expectations and Best Practices

While engineered for durability, proper care extends service life and ensures optimal performance.5 blade Sterndrive Propeller

Recommended Maintenance Practices

-

Rinse thoroughly after saltwater use

-

Inspect blades periodically for damage

-

Verify hub and mounting hardware condition

-

Address minor surface damage promptly

These practices help preserve both performance and safety over the long term.

Longevity as a Performance Advantage

Frequent replacement of propulsion components introduces inconsistency and downtime. This propeller has been designed to remain a reliable performance asset rather than a consumable upgrade.5 blade Sterndrive Propeller

Long-Term Ownership Benefits

-

Reduced replacement frequency

-

Consistent performance season after season

-

Lower total cost of ownership over time

Durability becomes a performance feature when reliability supports confidence on the water.

Inclusive Reliability for Diverse Operating Profiles

Not all performance boating looks the same. Some operators prioritize frequent high-speed runs, while others demand reliability during extended cruising. This propeller accommodates both profiles without requiring compromise.

Inclusive engineering ensures that durability benefits are realized regardless of how performance is applied.

Additional information

| Pitch | 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40 |

|---|---|

| Diameter | 15.00, 15.25, 15.50, 15.75, 16.00, 16.25, 16.50, 16.75, 17.00, 17.25, 17.50, 17.75, 18.00 |

| Rotation | LF, RH |

| Rake | 15, 18, 21 |

| Power | 1500, 600, 900, 1200 |

Reviews

There are no reviews yet.