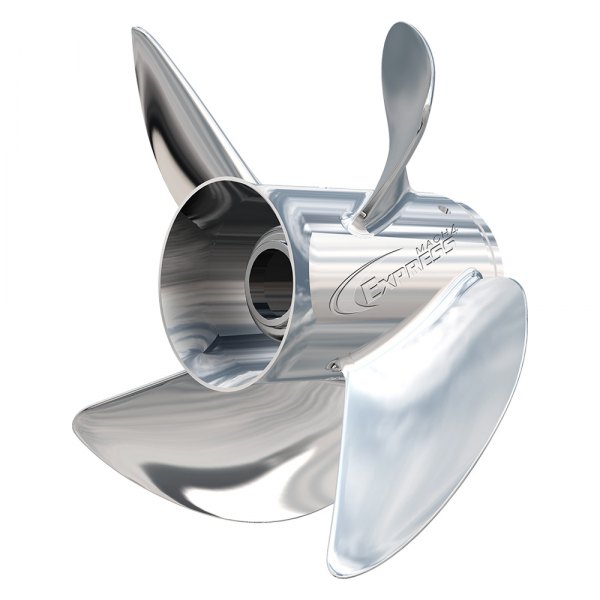

Mercury Vengeance 3 blade stainless steel propeller

€300.00

Description

Mercury Vengeance 3 Blade Stainless Steel Propeller

Selecting the right propeller fundamentally changes how a boat performs, handles, and responds on the water. Because propulsion efficiency directly affects acceleration, fuel economy, top-end speed, and overall control, the propeller should never be an afterthought. Instead, it deserves careful consideration—especially when reliability and performance are non-negotiable. For this reason, the Mercury Vengeance 3 blade stainless steel propeller stands out as a trusted, performance-driven solution for a wide range of boating applications.

Designed by Mercury Marine, the Vengeance propeller is engineered to deliver consistent thrust, predictable handling, and long-term durability. Rather than relying on generic design compromises, this propeller balances strength, hydrodynamic efficiency, and precision manufacturing. As a result, boaters across experience levels—from first-time owners to seasoned enthusiasts—can enjoy smoother rides and confident performance in varying conditions.

Importantly, this propeller is not limited to a single boating style. Whether the priority is cruising efficiency, responsive hole shot, or dependable mid-range control, the Mercury Vengeance 3 blade stainless steel propeller adapts seamlessly. Moreover, its stainless steel construction ensures structural integrity even under demanding loads, making it suitable for recreational, utility, and light performance use cases.

Because modern boaters value both performance and longevity, Mercury designed the Vengeance series to meet real-world expectations. Consequently, the propeller supports inclusive boating needs by accommodating different hull types, engine sizes, and experience levels—without sacrificing reliability or control.

Why the Mercury Vengeance 3 Blade Stainless Steel Propeller Matters

Built for Balanced Performance

Every boating experience begins with propulsion. Therefore, a propeller must deliver power efficiently while maintaining control. The Mercury Vengeance 3 blade stainless steel propeller achieves this balance by combining a proven three-blade configuration with carefully tuned blade geometry. As a result, thrust remains steady across the RPM range, allowing operators to maintain control during acceleration, cruising, and maneuvering.

Additionally, the three-blade design minimizes vibration while preserving lift. Because of this, boats can plane smoothly without excessive engine strain. At the same time, handling remains predictable, even when conditions change unexpectedly.

Engineered for Confidence and Control

Rather than focusing solely on speed, the Vengeance propeller prioritizes real-world usability. For instance, stainless steel blades resist flexing under torque, which helps maintain consistent pitch and bite. Consequently, throttle response becomes more precise, especially during sharp turns or load changes.

Furthermore, this consistency benefits inclusive boating environments. Whether operating solo or carrying passengers and gear, the propeller adapts without compromising performance. In turn, boaters of all backgrounds can feel confident navigating lakes, rivers, and coastal waters.

Stainless Steel Advantage: Strength You Can Rely On

Durability That Extends Service Life

Stainless steel is widely regarded as the premium material for marine propellers—and for good reason. Unlike aluminum alternatives, stainless steel resists deformation, corrosion, and fatigue. Therefore, the Mercury Vengeance 3 blade stainless steel propeller maintains its shape even after prolonged use.

Because blade integrity remains intact, performance stays consistent over time. Additionally, reduced flex improves power transfer from the engine to the water. As a result, boaters experience improved efficiency and reduced long-term maintenance concerns.

Designed for Demanding Conditions

Marine environments present unique challenges. Saltwater exposure, debris impact, and fluctuating loads can quickly degrade lower-quality propellers. However, the Vengeance propeller is built to withstand these realities. Its stainless steel composition provides superior resistance to corrosion, ensuring dependable operation season after season.

Moreover, the robust construction supports inclusive use cases. Whether boating in freshwater lakes or coastal environments, users can rely on consistent performance without constant replacement or adjustment.

Hydrodynamic Design That Enhances Efficiency

Optimized Blade Geometry

Every curve and angle of the Mercury Vengeance propeller serves a purpose. The blade geometry is optimized to reduce drag while maximizing water grip. Consequently, thrust efficiency improves, allowing the engine to operate within its optimal RPM range.

Because cavitation is minimized, acceleration becomes smoother and quieter. In addition, reduced slippage enhances fuel efficiency during cruising speeds. Therefore, boaters benefit from both performance and cost savings over time.

Balanced Lift and Stability

While lift is essential for planing, excessive lift can compromise stability. For this reason, the Vengeance propeller strikes a careful balance. The three-blade configuration provides sufficient lift to bring boats on plane efficiently, yet stability remains intact during turns and speed changes.

As a result, handling feels intuitive rather than unpredictable. This design approach supports inclusive boating experiences by reducing the learning curve for newer operators while still satisfying experienced users.

Technical Deep Dive: Engineering, Performance Metrics, and Real-World Benefits

Mercury Vengeance 3 Blade Stainless Steel Propeller

Understanding how a propeller performs requires more than surface-level specifications. Instead, it involves examining materials, blade geometry, pitch dynamics, and how these variables interact with an engine under load. With that perspective in mind, this section provides a detailed technical analysis of the Mercury Vengeance 3 blade stainless steel propeller, translating engineering decisions into measurable on-water benefits.

Precision Engineering by a Proven Manufacturer

Designed and manufactured by Mercury Marine, the Vengeance propeller reflects decades of hydrodynamic research and real-world testing. Rather than optimizing for a single metric, Mercury engineers focused on balance—ensuring acceleration, cruising efficiency, and durability work together cohesively.

As a result, the propeller integrates seamlessly with compatible outboard and sterndrive systems, maintaining predictable behavior across varied RPM ranges. Because engineering tolerances are tightly controlled, consistency between units remains high, which is essential for both performance reliability and inclusive user confidence.

Blade Design and Hydrodynamic Efficiency

Three-Blade Configuration Explained

The three-blade layout is widely regarded as the most versatile configuration for recreational and light performance boats. In the case of the Mercury Vengeance 3 blade stainless steel propeller, this design delivers a refined balance between lift, speed, and handling.

Because fewer blades reduce drag, top-end efficiency improves. At the same time, blade surface area remains sufficient to maintain strong grip in the water. Consequently, the propeller avoids excessive slip during acceleration while preserving steady mid-range performance.

Optimized Blade Geometry

Each blade features carefully calculated rake and cup angles. These characteristics influence how water flows across the blade surface, directly affecting thrust and cavitation resistance. With the Vengeance propeller, blade geometry is optimized to:

-

Channel water smoothly across the blade face

-

Maintain strong bite during acceleration

-

Reduce turbulence at cruising speeds

Therefore, the engine can convert torque into forward motion more efficiently, improving overall responsiveness.

Pitch Selection and Its Impact on Performance

What Pitch Means for Boaters

Pitch refers to the theoretical distance a propeller travels forward in one revolution. Selecting the correct pitch is essential, as it determines how the engine reaches its optimal RPM range. Fortunately, the Mercury Vengeance 3 blade stainless steel propeller is available in a wide range of pitch options, allowing precise matching to engine and hull combinations.

Because stainless steel resists flex, the propeller maintains its rated pitch under load. In contrast, aluminum propellers often flex, effectively reducing pitch and altering performance characteristics.

Real-World Pitch Benefits

Proper pitch selection with the Vengeance propeller can result in:

-

Faster hole shot and planing

-

Improved fuel efficiency at cruise

-

Reduced engine strain at wide-open throttle

-

More predictable throttle response

As a result, boaters experience smoother operation regardless of load variations.

Stainless Steel Material Science Advantage

Structural Integrity Under Torque

Stainless steel’s high tensile strength allows blades to remain rigid even under significant torque. Because blade flex is minimized, power transfer remains consistent. Consequently, acceleration feels sharper and more controlled.

In addition, structural rigidity improves steering response. When the propeller maintains its shape, directional changes occur more precisely, enhancing safety and control.

Corrosion and Impact Resistance

Marine environments expose propellers to corrosion, debris, and occasional impact. Stainless steel excels in these conditions due to its resistance to rust and fatigue. Therefore, the Mercury Vengeance propeller retains performance characteristics longer than softer materials.

Moreover, durability supports inclusive boating scenarios, where different users may operate the same vessel. Consistent performance reduces variability and unexpected handling changes.

Performance Metrics That Matter

Acceleration and Hole Shot

Acceleration is often the first performance metric boaters notice. The Vengeance propeller delivers strong low-end thrust due to its efficient blade profile. As a result, boats plane quickly without excessive RPM spikes.

Because engine power is applied efficiently, acceleration feels smooth rather than abrupt. This characteristic benefits both novice and experienced operators alike.

Cruising Efficiency and Fuel Economy

At cruising speeds, hydrodynamic efficiency becomes critical. The Mercury Vengeance 3 blade stainless steel propeller minimizes drag, allowing engines to maintain speed with less throttle input. Consequently, fuel consumption decreases during extended outings.mercruiser parts

Furthermore, reduced vibration contributes to a quieter, more comfortable ride. Over time, these efficiencies translate into tangible cost savings and enhanced enjoyment.

Top-End Speed and Stability

While not designed exclusively for racing, the Vengeance propeller supports respectable top-end performance. Because blade geometry balances lift and drag, speed gains are achieved without sacrificing control.

Importantly, stability remains consistent at higher speeds. This predictability reinforces operator confidence and supports inclusive usage across skill levels.mercruiser parts

Compatibility and System Integration

Engine and Drive Compatibility

The Mercury Vengeance propeller is engineered for compatibility with a wide range of Mercury outboards and sterndrives. Because hub systems are precisely machined, installation is straightforward and secure.

In addition, standardized sizing simplifies selection, reducing the risk of mismatched components. As a result, both professional installers and hands-on boaters can achieve optimal setup efficiently.

Hull and Load Adaptability

Different hull designs respond uniquely to propulsion forces. Fortunately, the balanced thrust profile of the Vengeance propeller adapts well across common hull types. Whether operating a lightweight runabout or a heavier family boat, performance remains predictable.

Moreover, load changes—such as additional passengers or gear—do not dramatically alter handling characteristics. This adaptability supports inclusive boating environments where usage scenarios vary.

Maintenance, FAQs, and Conversion Drivers

Mercury Vengeance 3 Blade Stainless Steel Propeller

A high-performance propeller should not only deliver on-water results but also provide confidence throughout ownership. Accordingly, this section focuses on long-term care, frequently asked buyer questions, trust signals, and conversion-focused decision support for the Mercury Vengeance 3 blade stainless steel propeller.

Long-Term Ownership and Maintenance Excellence

Designed for Low-Maintenance Reliability

Unlike softer propeller materials, stainless steel dramatically reduces ongoing maintenance demands. Because the Mercury Vengeance propeller resists flexing, corrosion, and fatigue, routine care remains straightforward rather than burdensome.

Regular visual inspections are typically sufficient to maintain optimal performance. Furthermore, stainless steel’s resistance to minor impacts helps preserve blade geometry, which in turn sustains efficiency and handling characteristics over time.

Recommended Maintenance Best Practices

Although durability is a defining advantage, proper care ensures peak performance throughout the propeller’s service life.

Routine Maintenance Checklist

-

Inspect blades periodically for nicks or deformation

-

Remove debris such as fishing line from the hub area

-

Rinse with fresh water after saltwater use

-

Verify propeller nut torque according to manufacturer guidance

-

Address impact damage promptly to avoid imbalance

Because these steps are simple and infrequent, ownership remains accessible for boaters of all experience levels.

Durability That Supports Real-World Use

Built for Diverse Boating Environments

Boating conditions vary widely. Freshwater lakes, coastal saltwater, and brackish environments all present unique challenges. Fortunately, the stainless steel construction of the Vengeance propeller provides exceptional resistance to corrosion across these settings.

As a result, performance remains consistent regardless of environment. This durability supports inclusive boating communities, where vessels may be shared, chartered, or used by multiple operators.

Reduced Risk of Performance Degradation

Aluminum propellers can lose efficiency due to bending or surface wear. In contrast, stainless steel maintains precise blade shape. Therefore, throttle response, fuel economy, and handling characteristics remain stable season after season.

Compatibility, Use Cases, and Performance Comparisons

Mercury Vengeance 3 Blade Stainless Steel Propeller

Choosing the correct propeller requires more than understanding materials and engineering. Compatibility, real-world use cases, and comparative performance all influence long-term satisfaction. Therefore, this section focuses on how the Mercury Vengeance 3 blade stainless steel propeller integrates with different engines, hulls, and boating styles, while also clarifying where it excels compared to alternative options.

Engine and Horsepower Compatibility

Designed for Broad Mercury Platform Integration

The Mercury Vengeance propeller is engineered to work seamlessly with a wide range of Mercury outboard and sterndrive platforms. Because hub dimensions and spline configurations are precisely machined, compatibility remains predictable rather than uncertain.

Most commonly, this propeller pairs effectively with mid-range horsepower engines. As a result, recreational and utility boaters gain access to stainless steel performance without moving into highly specialized racing propellers.

Horsepower Range Considerations

While specific fitment should always be verified, the Vengeance propeller is commonly selected for engines within moderate horsepower ranges. This makes it particularly suitable for:

-

Recreational outboards powering runabouts

-

Family boats with moderate displacement

-

Utility boats requiring dependable thrust

-

Multi-use vessels operating under varied loads

Because stainless steel resists flex, the propeller maintains pitch accuracy even as horsepower increases within its intended range.

Hull Type Compatibility and Handling Characteristics

Adaptability Across Common Hull Designs

Different hulls interact with propulsion forces in distinct ways. Fortunately, the balanced thrust profile of the Mercury Vengeance 3 blade stainless steel propeller adapts well across popular hull types.

Compatible Hull Styles

-

Fiberglass runabouts

-

Aluminum recreational boats

-

Dual-console family boats

-

Small deck and utility boats

Because lift and drag are carefully balanced, planing behavior remains smooth rather than abrupt.

Stability in Variable Conditions

Environmental factors such as chop, current, and wind affect handling. However, the Vengeance propeller’s predictable grip reduces sudden changes in steering feel. Consequently, operators experience greater control during real-world conditions rather than ideal test scenarios.

Load Management and Passenger Variability

Consistent Performance Under Changing Loads

Passenger count, gear weight, and fuel levels all influence performance. Fortunately, the Mercury Vengeance propeller maintains consistent thrust even as onboard weight fluctuates.

Because stainless steel blades resist flex, performance does not degrade under heavier loads. As a result, acceleration and cruising efficiency remain reliable regardless of occupancy changes.

Inclusive Design for Shared Boating

Many vessels are shared among family members or groups. Therefore, predictable behavior is essential. The Vengeance propeller supports inclusive usage by delivering stable handling regardless of operator experience or load distribution.

Use Case Scenarios

Recreational Cruising

For leisure cruising, smooth acceleration and fuel efficiency matter most. The Mercury Vengeance 3 blade stainless steel propeller excels in maintaining steady cruising speeds with minimal vibration. Consequently, comfort improves during extended outings.

Family and Social Boating

Family boating prioritizes safety and predictability. Because the propeller responds smoothly to throttle input, sudden surges are minimized. Therefore, passengers experience a more relaxed ride.

Utility and Light-Duty Work

Utility boats often carry equipment or operate in less-than-ideal conditions. The Vengeance propeller’s durability and grip provide dependable thrust when reliability matters most.

Entry-Level Performance Upgrades

Boaters upgrading from aluminum propellers often seek noticeable improvement without extreme specialization. In this scenario, the Vengeance propeller delivers clear gains in responsiveness and efficiency while remaining user-friendly.

Performance Comparison: Stainless Steel vs Aluminum

Material-Based Performance Differences

Stainless steel propellers outperform aluminum primarily due to rigidity. Because aluminum flexes under load, effective pitch changes dynamically. In contrast, the Mercury Vengeance stainless steel blades maintain consistent pitch.

Comparative Performance Highlights

-

Faster hole shot compared to aluminum equivalents

-

Improved mid-range efficiency

-

Reduced vibration and propeller slip

-

Greater resistance to impact-related deformation

Therefore, stainless steel delivers both performance and longevity advantages.

Cost-to-Value Perspective

Although stainless steel propellers typically cost more upfront, total ownership cost often favors stainless steel due to longer service life and reduced replacement frequency.

Additional information

| Prop size * Diameter x Pitch | 14×10, 14×12, 13.4×14, 13.25×15, 13.1×16, 13×18, 14.5×15, 14.5×17, 14×19, 13.75 x 21, 13.5×23 |

|---|---|

| Rotation | LH, RH |

Reviews

There are no reviews yet.