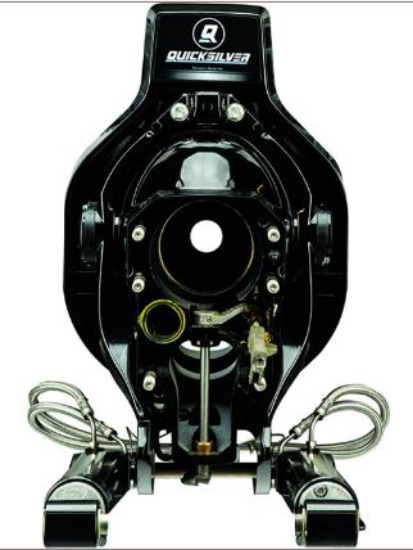

Mercury Quicksilver 6-61000004P Alpha 1 Gen 2 Transom

€2,170.00

Quicksilver 1994-2016 Alpha One Gen2 Complete Transom Assembly (commonly referredto as Gimbal Housing Assy)

Includes a Quicksilver factory repower reference manual.

For use with single or twin engine installations in boats up to 65 MPH using gasengines up to 300 HP using the Alpha One Gen II sterndrive.

1 year factory warranty. For sterndrive engineswithout an engine mounted seawater pump.Contact us if you have closed cooling on your Alpha engine.

Quicksilver Transoms are built to repower the most popular sterndrive engines in the world!

Quicksilver transoms are compatible with MerCruiser, Quicksilver andMercury Remanufacturing engines. A transom is one of the mostimportant components powering a sterndrive boat because of the manycritical systems that it manages:

Steering actuation

Trim control, sensing, and limit

Exhaust management

Cooling water handling

Corrosion control

The important function of keeping water out of the boat

Description

Quicksilver MerCruiser Alpha Gen 2 Transom – Built for Reliability, Engineered for Confidence

Across modern marine propulsion systems, dependable transom assemblies are relied upon as the structural and functional backbone of stern drive performance. For that reason, the Quicksilver MerCruiser Alpha Gen 2 Transom has been designed to support long-term durability, operational efficiency, and peace of mind for boat owners, technicians, and marine professionals alike.

From the outset, performance expectations have been elevated through precise engineering and material integrity. As a result, consistent power transfer, improved sealing, and dependable steering control are delivered across a wide range of boating conditions. Moreover, compatibility with Alpha Gen 2 drive systems has been ensured to reduce installation complexity and minimize long-term maintenance concerns.

Because reliability on the water is never optional, every component within the Quicksilver MerCruiser Alpha Gen 2 Transom assembly has been manufactured to meet or exceed original equipment standards. Consequently, confidence is reinforced for everyone involved—from first-time boat owners to experienced marine installers.

Why the Quicksilver MerCruiser Alpha Gen 2 Transom Matters

At the core of stern drive functionality, the transom assembly is responsible for supporting propulsion loads, steering forces, and sealing requirements simultaneously. When this critical component is compromised, performance degradation and safety risks are often introduced. Therefore, the Quicksilver MerCruiser Alpha Gen 2 Transom has been purpose-built to address these challenges proactively.

Rather than being treated as a simple mounting structure, the transom assembly has been engineered as an integrated system. Through this approach, alignment accuracy, vibration control, and water intrusion prevention are enhanced. As a result, smoother operation and extended service life are consistently achieved.

In addition, attention has been directed toward real-world usage scenarios. Because boats are operated in diverse environments, corrosion resistance and material resilience have been prioritized. Consequently, dependable performance has been maintained in both freshwater and saltwater applications.

Designed for Alpha Gen 2 Compatibility and Precision Fit

Optimized Integration with Alpha Gen 2 Drives

Compatibility has been treated as a foundational requirement rather than an afterthought. Specifically, the Quicksilver MerCruiser Alpha Gen 2 Transom has been manufactured to align precisely with Alpha Gen 2 stern drive systems. Through this precision, installation accuracy is improved and unnecessary modifications are avoided.

Furthermore, proper alignment between the engine, gimbal housing, and drive unit is supported. Because misalignment is a leading cause of premature wear, this design focus contributes directly to long-term reliability. As a result, smoother power delivery and reduced drivetrain stress are experienced over time.

Reduced Installation Complexity

Installation efficiency has been enhanced through thoughtful engineering. By incorporating standardized mounting points and OEM-matched dimensions, the transom assembly is positioned accurately during installation. Therefore, labor time is often reduced, and installation errors are minimized.

Additionally, compatibility with existing Alpha Gen 2 components allows for seamless replacement scenarios. In this way, downtime is reduced, and vessels are returned to service more quickly.

Engineered Materials for Marine Environments

Corrosion Resistance That Supports Longevity

Marine environments are inherently harsh, particularly in saltwater conditions. For that reason, corrosion-resistant materials have been selected for the Quicksilver MerCruiser Alpha Gen 2 Transom. Through this material strategy, structural integrity is preserved even after prolonged exposure to moisture and marine contaminants.

Protective coatings and marine-grade alloys have been utilized to resist oxidation and pitting. Consequently, long-term appearance and functional performance are maintained with reduced maintenance demands.

Structural Strength Without Excess Weight

While strength is essential, unnecessary weight can negatively impact vessel handling and efficiency. Therefore, material selection has been balanced carefully. Through advanced engineering, structural rigidity has been achieved without excessive mass.

As a result, hull stress is managed effectively while overall boat performance remains optimized. Moreover, improved balance and responsiveness are often noticed during operation.

Key Functional Advantages of the Quicksilver MerCruiser Alpha Gen 2 Transom

To support informed purchasing decisions, the primary benefits of this transom assembly have been highlighted below. Each advantage has been engineered to deliver practical, real-world value.

Highlighted Product Advantages

-

OEM-Matched Precision Fit

Alignment accuracy has been ensured to support proper engine and drive positioning. -

Enhanced Water Sealing

Water intrusion risks have been reduced through improved sealing surfaces and gasket compatibility. -

Corrosion-Resistant Construction

Long-term durability has been supported in both freshwater and saltwater environments. -

Optimized Steering and Handling Support

Steering loads have been managed effectively for smoother, more predictable control. -

Reduced Maintenance Over Time

Wear-related issues have been minimized through improved material quality and design. -

Installer-Friendly Design

Installation efficiency has been improved through standardized mounting and alignment features.

Supporting Performance, Safety, and Peace of Mind

Performance gains are only meaningful when safety is preserved. For that reason, the Quicksilver MerCruiser Alpha Gen 2 Transom has been engineered to support both operational performance and structural safety. Through proper load distribution and secure mounting, propulsion forces are transferred reliably to the hull.

Because steering response and drive stability are directly influenced by the transom assembly, predictable handling is supported under varying conditions. Consequently, confidence is reinforced for operators navigating calm waters or challenging environments alike.

Moreover, peace of mind is extended beyond the operator to installers and service professionals. When components are engineered correctly, fewer post-installation issues are encountered. As a result, trust is strengthened throughout the ownership and service lifecycle.

Ideal Use Cases for the Quicksilver MerCruiser Alpha Gen 2 Transom

Replacement and Restoration Projects

For aging vessels requiring structural renewal, this transom assembly has been positioned as a reliable replacement solution. Because OEM specifications are met, original performance characteristics are restored effectively.

Preventive Maintenance Upgrades

In preventive maintenance scenarios, proactive replacement of worn transom components is often recommended. Through early intervention, more costly drivetrain or hull repairs are frequently avoided.

Professional Marine Service Installations

For marine technicians and service centers, consistency and reliability are essential. Therefore, this transom assembly has been engineered to meet professional expectations for fit, finish, and performance.

A Foundation for Long-Term Value

Value is not measured solely at the point of purchase. Instead, long-term reliability, reduced maintenance, and sustained performance determine true ownership value. With the Quicksilver MerCruiser Alpha Gen 2 Transom, these factors have been addressed comprehensively.

Through precise engineering, marine-grade materials, and compatibility assurance, a dependable foundation has been established for Alpha Gen 2 stern drive systems. Consequently, investment protection and boating enjoyment are supported for years to come.

Technical Architecture of the Quicksilver MerCruiser Alpha Gen 2 Transom

Within marine propulsion systems, technical precision is relied upon to ensure safe and efficient operation. For this reason, the Quicksilver MerCruiser Alpha Gen 2 Transom has been constructed using an integrated architectural approach. Rather than functioning as an isolated mounting surface, the transom assembly has been engineered as a load-bearing and sealing-critical system.

Through this design philosophy, multiple mechanical forces are managed simultaneously. Propulsion torque, steering pressure, and vertical thrust loads are distributed evenly across the transom structure. As a result, component stress is reduced and operational stability is enhanced.

Additionally, dimensional tolerances have been held to exacting standards. Because alignment accuracy directly influences drivetrain longevity, these tolerances have been preserved throughout the manufacturing process.

Component Breakdown and Functional Roles

Inner Transom Plate and Structural Reinforcement

At the internal interface, the inner transom plate has been engineered to reinforce hull integrity. Load transfer from the engine and drive assembly is absorbed efficiently, ensuring hull stress is minimized over extended use.

Moreover, reinforcement geometry has been optimized to prevent flex under heavy acceleration or directional changes. Consequently, consistent handling characteristics are maintained.

Outer Transom Assembly and Drive Interface

Externally, the outer transom assembly serves as the primary interface between the hull and the stern drive. Through this interface, propulsion forces are transferred while maintaining a watertight seal.

Precision-machined surfaces have been incorporated to ensure proper seating of gimbal housings and drive components. Therefore, vibration and noise are reduced during operation.

Gimbal Housing Support Integration

Support for the gimbal housing has been incorporated directly into the transom design. Because steering precision is dependent on gimbal stability, this integration enhances directional control.

As a result, smoother steering response is delivered across varying speeds and water conditions.

Advanced Sealing Systems for Water Intrusion Prevention

Multi-Layer Seal Design

Water intrusion is widely recognized as one of the most damaging risks to marine propulsion systems. To address this concern, the Quicksilver MerCruiser Alpha Gen 2 Transom has been engineered with a multi-layer sealing approach.

Through the use of layered gaskets and precision-machined sealing surfaces, water ingress points are minimized. Consequently, internal components are protected from corrosion and premature failure.

Compatibility with OEM Gaskets and Sealants

OEM-compatible gasket profiles have been supported to ensure seamless replacement and servicing. Because standardized components are preferred in marine service environments, maintenance flexibility is preserved.

Additionally, compatibility with approved marine sealants allows for enhanced sealing assurance during installation.

Performance Benefits Delivered Through Engineering Precision

Improved Power Transfer Efficiency

Efficient power transfer is achieved when alignment and rigidity are preserved. Through reinforced structural geometry, drivetrain energy loss is minimized.

As a result, smoother acceleration and consistent propulsion output are delivered under load.

Reduced Vibration and Operational Noise

Vibration damping has been achieved through material selection and structural reinforcement. Because excessive vibration contributes to fatigue and component wear, this design element supports long-term reliability.

Furthermore, reduced operational noise contributes to a more comfortable onboard experience.

Enhanced Steering Stability

Steering loads are absorbed and distributed effectively through the integrated transom design. Consequently, predictable handling and directional control are supported even during aggressive maneuvers.

Installation Considerations and Professional Advantages

Installer-Focused Engineering

Marine installers often prioritize consistency and predictability. Therefore, the Quicksilver MerCruiser Alpha Gen 2 Transom has been designed with installer efficiency in mind.

Mounting points have been standardized, and alignment references have been incorporated. As a result, installation time is often reduced while accuracy is improved.

Reduced Risk of Post-Installation Adjustments

Because dimensional accuracy is preserved, post-installation adjustments are minimized. This benefit supports both professional service providers and vessel owners by reducing downtime.

Additionally, fewer alignment-related issues are encountered during initial sea trials.

Highlighted Technical Advantages for Buyers and Installers

To support clarity and conversion, the following technical advantages have been emphasized:

-

Precision-Machined Interfaces

Accurate mating surfaces support proper alignment and sealing. -

Integrated Load Distribution Design

Propulsion and steering forces are managed evenly. -

Multi-Layer Water Sealing System

Long-term protection against water intrusion is provided. -

OEM-Compatible Component Geometry

Replacement and servicing are simplified. -

Reduced Vibration Transmission

Comfort and component longevity are enhanced. -

Installer-Optimized Mounting Configuration

Labor efficiency and accuracy are improved.

Long-Term Reliability Through Preventive Engineering

Rather than relying on reactive durability, preventive engineering principles have been applied throughout the transom assembly. By addressing known failure points proactively, long-term reliability has been supported.

Corrosion pathways have been minimized, alignment degradation has been reduced, and structural fatigue has been mitigated. Consequently, service intervals are often extended and unexpected failures are less likely to occur.

This approach delivers value not only during initial ownership, but throughout the operational life of the vessel.

Supporting Inclusive Ownership and Confidence

Boat ownership includes a wide range of experience levels, from seasoned professionals to first-time operators. For that reason, inclusive design considerations have been applied.

By supporting straightforward installation, predictable performance, and reduced maintenance demands, confidence is extended to everyone involved. As a result, ownership stress is reduced and enjoyment on the water is increased.

Comparative Value of the Quicksilver MerCruiser Alpha Gen 2 Transom

When evaluated against aftermarket or non-matched transom alternatives, meaningful distinctions are revealed. Rather than relying on generic dimensions or adaptable fittings, the Quicksilver MerCruiser Alpha Gen 2 Transom has been engineered with system-specific intent. Through this approach, performance consistency and installation confidence are preserved.

In comparison scenarios, misalignment risk, sealing inconsistencies, and accelerated wear are frequently associated with non-OEM-matched components. Conversely, these issues are proactively addressed through precision engineering and compatibility assurance. As a result, long-term ownership costs are often reduced.

Additionally, value differentiation is reinforced through predictable performance outcomes. Because consistency is prioritized, uncertainty is minimized for buyers and installers alike.

Durability Validation and Real-World Stress Considerations

Engineered to Withstand Continuous Load Cycles

Marine propulsion systems are subjected to repeated load cycles over extended periods. For that reason, structural fatigue resistance has been embedded into the transom design.

Through reinforced geometry and material resilience, deformation under stress has been minimized. Consequently, alignment stability is maintained even after prolonged operation.

Resistance to Environmental Degradation

Environmental exposure presents ongoing challenges in marine applications. Therefore, resistance to moisture, salinity, and temperature variation has been addressed during material selection and surface treatment.

Protective coatings and corrosion-resistant alloys work together to preserve structural integrity. As a result, dependable performance is sustained across seasonal and geographic variations.

Use-Case Scenarios That Highlight Practical Value

High-Usage Recreational Vessels

For vessels operated frequently, component longevity becomes critical. In these scenarios, the Quicksilver MerCruiser Alpha Gen 2 Transom supports consistent performance while reducing the likelihood of unexpected service interruptions.

Through durability-focused engineering, reliability expectations are met even under demanding usage patterns.

Family and Leisure Boating Applications

In leisure-focused environments, safety and predictability are prioritized. Because steering stability and sealing integrity are supported, confidence is reinforced for all onboard participants.

Moreover, inclusive usability ensures that operators of varying experience levels are supported equally.

Commercial and Service-Oriented Operations

For charter, training, or service vessels, downtime directly impacts operational efficiency. Therefore, components that support extended service intervals are essential.

By minimizing wear-related failures, this transom assembly contributes to predictable maintenance planning and operational continuity.

Buyer-Focused Benefits That Support Confident Decisions

Reduced Total Cost of Ownership

Although initial purchase decisions are important, long-term costs often define true value. Through reduced maintenance demands and extended service life, overall ownership costs are commonly lowered.

As a result, financial predictability is improved throughout the lifecycle of the vessel.

Simplified Maintenance Planning

Because compatibility with OEM components is preserved, maintenance planning is simplified. Replacement parts are sourced more easily, and service procedures remain standardized.

Consequently, both professional service providers and individual owners benefit from reduced complexity.

Confidence Through Proven Engineering

Trust is built when engineering decisions are transparent and outcomes are predictable. Through adherence to OEM standards and preventive design principles, confidence is reinforced at every stage of ownership.

To further support conversion-focused evaluation, the following buyer-oriented advantages are emphasized:

-

System-Specific Engineering

Compatibility risks are reduced through Alpha Gen 2-focused design. -

Long-Term Structural Stability

Fatigue resistance supports extended operational life. -

Environmental Resilience

Corrosion and moisture-related degradation are minimized. -

Predictable Performance Outcomes

Handling and propulsion consistency are maintained. -

Lower Lifecycle Maintenance Impact

Ownership costs are reduced over time. -

Inclusive Usability Across Experience Levels

Confidence is supported for all operators.

Reviews

There are no reviews yet.