Mercury Quicksilver 5-51100008P Alpha 1 Gen 2 Sterndrive 1.47 Ratio

€1,845.00

Mercury Quicksilver 5-51100008P 1.47:1 ratio Standard Rotation (RH)

Recommended for use with Quicksilver 350 MPI Alpha sterndrive engines

- 1year limited factory warranty

- Low maintenance

- Durable

- Strong

- Quiet

- Corrosion Resistant

- Repair anywhere in the world

Using proprietary forged gear sets, Quicksilver Alpha 1 Gen 2 sterndrives provide years of durable and quiet operation for a safe andsophisticated boating experience like none other. Compatible withFlo-Torq II hubs & engines using remote drive lube reservoirs toprotect your investment.

Quicksilver sterndrives feature: perma-lubeU-joints, corrosion resistant XK-360 alloy, a tri-paint protection system,stainless steel shafts, ultra-pure aluminum anodes and a genuineQuicksilver water pump impeller.

Includes a Quicksilver Repower Reference Manual covering all aspects of proper application and installation!

Description

Quicksilver MerCruiser Alpha One Gen II Outdrive 1.47:1

In modern marine propulsion, reliability is consistently demanded, efficiency is continuously evaluated, and durability is universally expected. Accordingly, the Quicksilver MerCruiser Alpha One Gen II Outdrive 1.47:1 has been positioned as a benchmark solution for recreational and light-duty commercial boating applications. From the outset, this outdrive has been engineered to deliver dependable power transfer, balanced torque distribution, and long-term operational confidence.

Moreover, performance expectations have been elevated across boating communities; therefore, propulsion systems are increasingly scrutinized for compatibility, longevity, and serviceability. In response, the Alpha One Gen II platform has been refined and reinforced. Consequently, a propulsion solution has been delivered that continues to be trusted across inland waterways, coastal environments, and high-use recreational settings.

What the Alpha One Gen II Outdrive Represents

At its core, the Quicksilver MerCruiser Alpha One Gen II Outdrive 1.47:1 is designed to function as the critical link between engine output and propeller thrust. Specifically, engine power is transferred through a precision-engineered gearcase, after which controlled propulsion is achieved. As a result, smooth acceleration, predictable handling, and optimized fuel efficiency are consistently realized.

Additionally, the 1.47:1 gear ratio has been carefully selected to support a wide range of engine configurations. Consequently, balanced RPM ranges are maintained, propeller efficiency is enhanced, and mechanical stress is effectively moderated. Therefore, vessel performance is preserved while component wear is reduced over extended operating cycles.

Evolution of the Gen II Design

Historically, earlier Alpha One configurations were widely adopted; however, performance limitations were identified under higher torque demands. As a result, the Gen II iteration was developed with reinforced internals, improved bearing support, and enhanced corrosion protection.

Subsequently, structural rigidity has been increased, sealing systems have been improved, and maintenance intervals have been extended. In turn, reliability has been strengthened while ownership costs have been reduced. Therefore, this outdrive has remained relevant even as engine technologies and boating expectations have advanced.

Intended Applications and Use Cases

The Alpha One Gen II Outdrive 1.47:1 has been purpose-built for versatility. Accordingly, compatibility has been achieved across numerous boat styles and engine pairings.

Typical applications include:

-

Runabouts and bowriders

-

Sport boats and performance cruisers

-

Small cabin cruisers

-

Light commercial and utility vessels

Furthermore, inclusive design considerations have ensured that both experienced marine technicians and first-time boat owners are supported. As a result, installation guidance, service documentation, and replacement part availability have been standardized across the platform.

Key Functional Advantages at a Glance

To clarify its value proposition, the most critical functional benefits are outlined below. Not only are these advantages measurable, but they are also repeatedly validated through real-world use.

Highlighted Product Advantages

-

Optimized 1.47:1 gear ratio for balanced acceleration and cruising efficiency

-

Hardened internal gears engineered for consistent torque transfer

-

Enhanced corrosion resistance, suitable for freshwater and saltwater environments

-

Improved sealing architecture to reduce water intrusion risks

-

Broad engine compatibility, simplifying repower and replacement decisions

Accordingly, confidence is built at every stage of ownership—from selection and installation to daily operation and long-term maintenance.

Why Gear Ratio Matters in Real-World Performance

Gear ratio selection is often misunderstood; however, its impact is substantial. In this configuration, the 1.47:1 ratio allows propeller rotation to be carefully synchronized with engine RPM. Consequently, excessive engine strain is avoided, while usable power is effectively translated into forward thrust.

Moreover, smoother planing characteristics are achieved, vibration is minimized, and predictable throttle response is delivered. Therefore, operators are empowered with greater control, particularly during docking, towing, and variable load conditions.

Engineering Philosophy Behind Quicksilver MerCruiser

Across all Quicksilver MerCruiser propulsion products, engineering decisions have been driven by field data, long-term testing, and end-user feedback. Accordingly, materials have been selected for resilience, tolerances have been tightened for precision, and modularity has been emphasized for service efficiency.

As a result, the Alpha One Gen II Outdrive 1.47:1 is not merely a replacement component; instead, it is positioned as a system-level upgrade that enhances overall vessel performance.

Setting Expectations for Long-Term Ownership

Ownership considerations extend beyond initial purchase decisions. Therefore, durability, parts availability, and service support have been prioritized throughout the design lifecycle. Consequently, maintenance procedures are streamlined, replacement components are widely accessible, and service downtime is minimized.

Furthermore, inclusive documentation ensures that professional technicians and hands-on owners alike are supported. In this way, confidence is sustained throughout years of operation.

Technical Architecture and Engineering Breakdown

Precision Engineering at the Core of the System

Within the marine propulsion sector, engineering precision is regarded as a decisive factor in long-term reliability. Accordingly, the Quicksilver MerCruiser Alpha One Gen II Outdrive 1.47:1 has been engineered as an integrated mechanical system rather than a collection of isolated components. As a result, consistent power delivery, structural balance, and mechanical efficiency are achieved across diverse operating conditions.

From the initial design phase, tolerances have been tightened, load paths have been optimized, and component interaction has been refined. Therefore, operational stress is distributed evenly, while premature wear is effectively minimized.

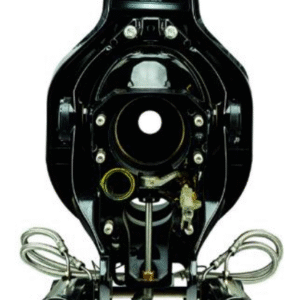

Upper Gearcase Construction and Functionality

The upper gearcase has been designed to manage rotational input directly from the engine coupler. Consequently, vertical drive transmission is stabilized before power is transferred downward to the lower unit.

Within this assembly, hardened steel gears are supported by reinforced bearings. As a result, torque fluctuations are absorbed smoothly, and rotational consistency is maintained. Furthermore, internal alignment has been enhanced in the Gen II platform, ensuring vibration reduction and improved noise control.

Upper Gearcase Engineering Highlights

-

Precision-cut gears for efficient rotational transfer

-

Reinforced bearing supports for load stabilization

-

Improved lubrication pathways for thermal control

-

Enhanced housing rigidity to reduce flex under load

Accordingly, long-term drivetrain stability is preserved even during extended high-RPM operation.

Lower Unit Gearcase and Propulsion Efficiency

Below the waterline, the lower unit performs the critical task of converting rotational energy into usable thrust. In this configuration, the 1.47:1 gear ratio has been integrated to balance torque multiplication with propeller speed.

As a result, smoother hole-shot performance is delivered, while cruising efficiency is preserved. Additionally, cavitation risk is reduced due to controlled propeller rotation. Therefore, predictable handling and improved fuel economy are consistently achieved.

Lower Unit Functional Advantages

-

Optimized hydrodynamic housing profile

-

Hardened forward and reverse gears

-

Efficient thrust bearing design

-

Improved oil retention and circulation

Consequently, propulsion efficiency is maximized without sacrificing durability.

Driveshaft, Propshaft, and Power Transfer Alignment

Power transmission integrity is dependent on precise shaft alignment. For this reason, the Alpha One Gen II system has been designed with improved shaft metallurgy and dimensional accuracy.

The vertical driveshaft is responsible for transferring engine power downward, while the horizontal propshaft delivers torque directly to the propeller. Accordingly, load balancing has been engineered into both shafts to reduce torsional stress.

Moreover, spline engagement surfaces have been strengthened. As a result, power loss is minimized, and long-term wear is reduced.

Sealing Systems and Water Intrusion Prevention

Water intrusion is recognized as one of the most common causes of outdrive failure. Therefore, advanced sealing architecture has been incorporated throughout the Alpha One Gen II design.

Multiple sealing points are utilized along shaft interfaces, gearcase joints, and service access locations. Consequently, water contamination risks are significantly reduced, even in variable temperature and salinity conditions.

Sealing and Protection Features

-

Multi-lip shaft seals for redundancy

-

Improved gasket materials for longevity

-

Enhanced venting to manage pressure changes

-

Corrosion-resistant fasteners and housings

As a result, internal components remain protected, and service intervals are extended.

Corrosion Resistance and Material Selection

Marine environments are inherently aggressive; therefore, corrosion resistance has been treated as a primary engineering requirement. Accordingly, aluminum alloy housings have been treated with advanced protective coatings.

Additionally, sacrificial anode compatibility has been integrated into the system. As a result, electrochemical corrosion is managed proactively. Therefore, structural integrity is preserved across freshwater and saltwater applications.

Lubrication System and Thermal Management

Effective lubrication is essential for gear longevity and thermal stability. In this system, gear oil circulation has been optimized to ensure consistent coverage across all moving components.

As rotational motion occurs, lubricant is distributed evenly throughout the gearcase. Consequently, friction is reduced, operating temperatures are stabilized, and mechanical efficiency is maintained.

Furthermore, oil inspection and replacement procedures have been simplified. Therefore, routine maintenance is made more accessible for inclusive ownership experiences.

Compatibility with Engine Platforms

Broad compatibility has been engineered into the Alpha One Gen II Outdrive 1.47:1. As a result, pairing with a wide range of gasoline marine engines is supported.

This design philosophy has been maintained by Quicksilver MerCruiser, ensuring standardized mounting dimensions, coupler interfaces, and shift mechanisms. Consequently, repower projects and replacements are simplified, while installation risks are reduced.

Structural Reinforcements Unique to Gen II

Compared to earlier generations, the Gen II architecture incorporates additional reinforcement in high-load zones. Specifically, bearing carriers, gear hubs, and housing ribs have been strengthened.

As a result, higher torque thresholds are accommodated, and fatigue resistance is improved. Therefore, operational confidence is enhanced across demanding use cases such as towing, watersports, and extended cruising.

Performance Characteristics and Real-World Operating Benefits

Performance Outcomes Engineered Into Everyday Operation

Across recreational and light-duty marine environments, performance is not evaluated solely by peak speed figures. Instead, responsiveness, consistency, and control are measured over repeated operating cycles. Accordingly, the Quicksilver MerCruiser Alpha One Gen II Outdrive 1.47:1 has been engineered to deliver balanced, repeatable performance rather than short-term output gains.

From initial throttle engagement through sustained cruising, propulsion behavior has been refined to support predictable vessel response. As a result, operator confidence is strengthened, and passenger comfort is consistently improved.

Acceleration and Hole-Shot Optimization

During low-speed acceleration, mechanical efficiency is critically important. In this configuration, the 1.47:1 gear ratio allows torque to be multiplied effectively without excessive engine strain. Consequently, faster planing is achieved, while engine RPM is kept within optimal operating ranges.

Moreover, smoother hole-shot performance is delivered even under variable load conditions. Therefore, towing applications, passenger-heavy outings, and gear-laden excursions are handled with greater consistency.

Acceleration-Focused Advantages

-

Faster transition from displacement to planing

-

Reduced throttle lag during takeoff

-

Controlled RPM rise under load

-

Improved responsiveness during maneuvering

As a result, performance remains accessible rather than aggressive, supporting inclusive use across experience levels.

Cruising Efficiency and Fuel Economy Impact

At cruising speeds, efficiency becomes the dominant performance metric. Accordingly, gear synchronization within the Alpha One Gen II Outdrive 1.47:1 has been optimized to reduce parasitic losses.

Because propeller rotation is matched more precisely to engine output, unnecessary fuel consumption is minimized. Consequently, longer cruising ranges are achieved, and refueling intervals are extended.

Furthermore, reduced vibration and smoother power delivery contribute to improved combustion efficiency. Therefore, operational costs are lowered over the long term without compromising on usable performance.

Handling Precision and Throttle Control

Handling characteristics are directly influenced by propulsion predictability. In this system, torque delivery has been stabilized to prevent abrupt thrust changes. As a result, steering input remains consistent, and vessel tracking is improved.

During docking, slow-speed maneuvering, and confined navigation scenarios, precise throttle modulation is enabled. Consequently, stress is reduced for operators, particularly in crowded marinas or adverse weather conditions.

Additionally, smoother reverse engagement has been engineered. Therefore, backing control is enhanced, and docking confidence is reinforced.

Load Management and Stability Under Stress

Marine propulsion systems are frequently subjected to fluctuating loads. Accordingly, structural and mechanical stability has been prioritized in the Alpha One Gen II design.

Under heavy passenger loads or towing scenarios, torque distribution remains controlled. As a result, excessive drivetrain shock is avoided, and component longevity is preserved.

Moreover, consistent thrust output is maintained during wave interaction and chop. Therefore, vessel stability is enhanced, and operator fatigue is reduced over extended operating periods.

Noise, Vibration, and Harshness Reduction

Comfort considerations extend beyond seating and hull design. Therefore, vibration damping and noise reduction have been engineered directly into the outdrive system.

Through improved gear meshing, reinforced housings, and enhanced bearing alignment, operational noise has been reduced. Consequently, onboard communication is improved, and fatigue is minimized during long outings.

Additionally, smoother mechanical engagement contributes to a more refined boating experience. Thus, recreational enjoyment is elevated for all onboard participants.

Performance Consistency Across Conditions

Unlike systems optimized for narrow operating windows, the Alpha One Gen II Outdrive 1.47:1 has been tuned for consistency. As a result, performance remains stable across varying water conditions, temperature ranges, and usage patterns.

Whether operated in calm inland lakes or moderate coastal environments, predictable propulsion behavior is maintained. Therefore, planning confidence is strengthened, and unexpected performance deviations are minimized.

Conversion-Focused Performance Value Summary

From a buyer perspective, performance benefits must translate into tangible value. Accordingly, the following highlights summarize the real-world advantages delivered by this outdrive configuration.

Highlighted Performance Benefits

-

Balanced acceleration without excessive RPM stress

-

Improved cruising efficiency and fuel savings

-

Enhanced low-speed handling and docking control

-

Stable performance under variable load conditions

-

Reduced vibration for improved onboard comfort

As a result, purchasing decisions are supported not only by specifications, but by measurable, repeatable operational outcomes.

Installation Readiness, Compatibility Assurance, and Repower Considerations

Installation Confidence Built Into the Design

During propulsion system replacement or upgrade projects, installation complexity is often viewed as a critical risk factor. Accordingly, the Quicksilver MerCruiser Alpha One Gen II Outdrive 1.47:1 has been engineered to support predictable, repeatable installation outcomes. From mounting geometry to control interfaces, standardized dimensions have been maintained to reduce variability.

As a result, installation procedures are simplified, alignment accuracy is improved, and commissioning time is reduced. Therefore, both professional installers and informed owners are supported through a streamlined deployment process.

Transom Assembly and Mounting Compatibility

Compatibility with existing transom assemblies has been treated as a foundational requirement. Consequently, the Alpha One Gen II platform has been designed to integrate seamlessly with compatible MerCruiser transom hardware.

Mounting bolt patterns, gimbal interfaces, and bell housing connections have been standardized. As a result, structural alignment is preserved, and improper load transfer is avoided.

Mounting Compatibility Highlights

-

Standardized Gen II bolt pattern alignment

-

Direct fit with compatible MerCruiser transom assemblies

-

Reinforced mounting points for load stability

-

Predictable trim and steering geometry

Accordingly, structural integrity is maintained without the need for extensive hull modification.

Alignment and Pre-Installation Verification

Before installation is finalized, proper alignment is essential. In this system, alignment tolerances have been clearly defined, allowing verification to be performed efficiently.

Engine coupler alignment, driveshaft engagement, and gimbal bearing positioning are evaluated during pre-installation checks. Consequently, drivetrain stress is minimized, and vibration-related issues are reduced.

Moreover, alignment tools and reference documentation are widely available. Therefore, installation accuracy is consistently achieved across service environments.

Control Systems and Shift Mechanism Integration

Shift control performance directly influences operator confidence. For this reason, shift cable routing and engagement geometry have been refined in the Alpha One Gen II design.

Smooth forward, neutral, and reverse engagement has been prioritized. As a result, gear changes are executed with reduced resistance and improved predictability.

Additionally, compatibility with existing control boxes has been preserved. Consequently, helm-side modifications are typically unnecessary, further reducing installation complexity.

Repower and Replacement Suitability

Repower projects require careful compatibility evaluation. Accordingly, the Alpha One Gen II Outdrive 1.47:1 has been positioned as a highly suitable solution for replacing earlier Alpha One variants.

Because mounting dimensions, control interfaces, and gearcase profiles have been retained, repower transitions are simplified. As a result, vessels benefit from modernized internals without extensive system redesign.

Repower-Friendly Advantages

-

Direct replacement compatibility for qualifying Alpha One setups

-

Improved durability without altering vessel configuration

-

Updated sealing and corrosion protection systems

-

Extended service life compared to legacy units

Therefore, value is preserved while performance and reliability are enhanced.

Engine Pairing Considerations

Proper engine pairing is essential for optimal performance. In this configuration, the 1.47:1 gear ratio has been selected to support a broad range of gasoline marine engines within approved torque limits.

When paired correctly, balanced RPM ranges are maintained, and propeller selection flexibility is increased. Consequently, both acceleration and cruising efficiency targets are achieved without mechanical compromise.

Guidance provided by Quicksilver MerCruiser ensures that approved engine combinations are clearly defined. Therefore, compatibility risks are minimized, and warranty considerations are protected.

Post-Installation Checks and Commissioning

After installation, commissioning procedures are performed to validate system integrity. Gear oil levels are verified, shift engagement is tested, and trim operation is confirmed.

As a result, early detection of installation-related issues is enabled. Consequently, corrective action is taken before operational use begins.

Furthermore, break-in recommendations are provided to support long-term durability. Therefore, component seating is optimized, and early wear is avoided.

Installation Value from a Buyer Perspective

From a purchasing standpoint, ease of installation translates directly into cost control and reduced downtime. Accordingly, the Alpha One Gen II Outdrive 1.47:1 delivers measurable value beyond specifications alone.

Installation and Compatibility Value Summary

-

Reduced labor complexity during installation

-

High confidence fitment for replacements and repowers

-

Broad control and transom compatibility

-

Lower risk of alignment-related failures

As a result, purchasing decisions are reinforced by practical deployment advantages.

Reviews

There are no reviews yet.