VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992

€1,100.00

Description

VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992

Precision-Engineered Rear Propulsion for Mercury Verado Systems

Performance on the water is never accidental. Instead, it is achieved through deliberate engineering, precise component matching, and uncompromising material standards. The VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992 has been developed to meet those exact expectations for boat owners who rely on Mercury Verado dual-prop outboard platforms.VERADO12 33 PITCH MERCURY RH 3 BLADE

Designed as a rear-position propeller within a counter-rotating configuration, this model plays a critical role in stabilizing thrust, optimizing efficiency, and ensuring predictable handling under load. Because propulsion balance matters, this propeller is manufactured to OEM specifications that align seamlessly with Verado gearcases.

Purpose-Built for Rear Counter-Rotating Applications

Why the VERADO12 33 PITCH MERCURY RH 3 BLADE Matters

In dual-prop systems, propulsion responsibilities are shared. While the forward propeller initiates thrust, the rear propeller refines it. As a result, steering authority is enhanced, torque steer is minimized, and cavitation risks are significantly reduced.MERCURY RH 3 BLADE

The 33-pitch rear configuration supports higher-speed operation while maintaining smooth power delivery. Consequently, engines operate within their intended RPM band more consistently, even during extended cruising or offshore runs.VERADO12 33 PITCH MERCURY RH 3 BLADE

VERADO12 33 PITCH MERCURY RH 3 BLADE Product Specifications

-

Product Series: VERADO12

-

Pitch: 33

-

Rotation: Right-Hand (RH)

-

Blade Count: 3-Blade Design

-

Mounting Position: Rear (Dual-Prop Systems)

-

Material: Marine-Grade Stainless Steel

-

OEM Part Number: 48-8M0166992

Each specification has been selected to support durability, balance, and long-term performance across demanding marine environments.

Performance Advantages You Can Expect

Enhanced Top-End Efficiency

Higher pitch allows for increased distance traveled per revolution. Therefore, cruising speeds are achieved with reduced throttle input when conditions allow.VERADO12 33 PITCH MERCURY RH 3 BLADE

Improved Directional Stability

Yaw and lateral drift are minimized because thrust is refined as it exits the gearcase. As a result, handling feels controlled and predictable.

Reduced Cavitation at Load

Blade geometry has been optimized to reduce air ingestion. Consequently, thrust remains consistent during tight turns and acceleration.

Smooth Power Transfer

Because this propeller is engineered for Verado systems, drivetrain harmonics remain balanced, which reduces vibration and wear.VERADO12 33 PITCH MERCURY RH 3 BLADE

Ideal Use Cases and Vessel Profiles

This rear propeller is especially well-suited for:

-

Offshore and nearshore cruising vessels

-

Performance-oriented center consoles

-

Boats operating at sustained higher speeds

-

Applications where smooth handling is prioritized

-

Owners seeking OEM reliability over aftermarket variability

MERCURY RH 3 BLADE OEM Stainless Steel Construction Benefits

Stainless steel is used not only for strength, but also for precision. Unlike aluminum alternatives, stainless steel maintains blade integrity under load. Therefore, pitch consistency is preserved over time, even in demanding conditions.VERADO12 33 PITCH MERCURY RH 3 BLADE

Additional benefits include:

-

Superior corrosion resistance

-

Long service life

-

Resistance to flex under torque

-

Consistent performance across RPM ranges

MERCURY RH 3 BLADE Compatibility and Fitment Guidance

The VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992 is designed for select Mercury Verado dual-prop outboard engines.

Because gearcase ratios, hull design, and horsepower vary, confirmation prior to installation is recommended. Proper matching ensures that both performance gains and engine longevity are preserved.

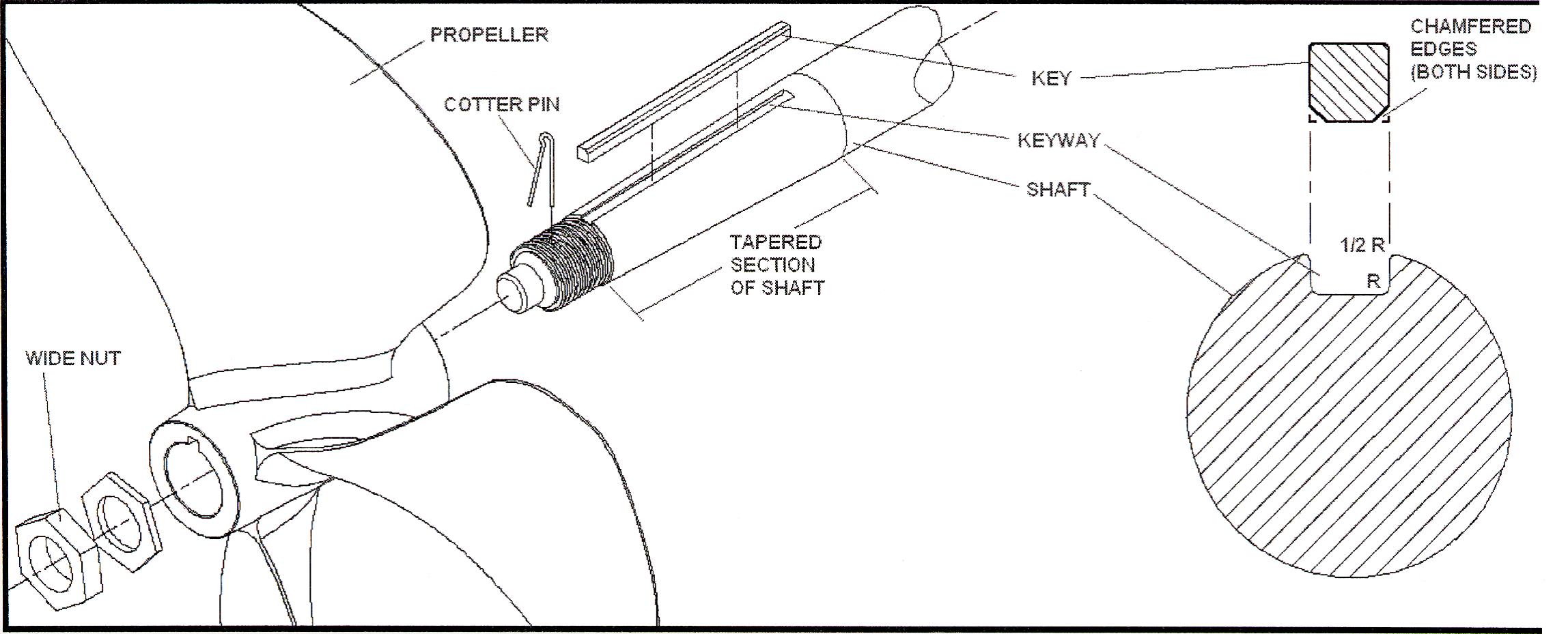

Installation and Ownership Considerations

Installation should be completed using manufacturer-recommended hardware and torque specifications. When installed correctly, vibration is minimized and propeller alignment remains optimal.VERADO12 33 PITCH MERCURY RH 3 BLADE

Routine inspections are advised, particularly after impact or prolonged high-speed operation. By maintaining proper care, performance consistency can be sustained over the long term.VERADO12 33 PITCH MERCURY RH 3 BLADE

Why Choose This Propeller Over Alternatives

Aftermarket propellers may appear similar; however, tolerances, metallurgy, and balance often differ. OEM Mercury propellers are designed alongside the engines they support. As a result, integration is seamless and predictable.

Choosing OEM means:

-

Correct RPM loading

-

Verified balance

-

Reduced drivetrain stress

-

Confidence at speed

How Propeller Design Influences Real-World Performance

Boat performance is not determined by engine horsepower alone. Instead, propulsion efficiency is shaped by how effectively engine power is converted into thrust. This conversion occurs at the propeller. Therefore, understanding pitch, blade geometry, and propeller position is essential when selecting a rear propeller for a Mercury Verado dual-prop system.

Because Verado engines operate within engineered tolerances, propeller selection must complement—not counteract—those parameters. When alignment is achieved, efficiency, control, and longevity are all improved.

Pitch Defined in Practical Terms

Propeller pitch represents the theoretical distance a propeller would move forward in one full revolution through a solid medium. In water, slip is introduced; however, pitch remains a primary determinant of speed and engine load.

A 33-pitch propeller is designed to move farther per rotation than lower-pitch alternatives. Consequently, higher speeds can be achieved with fewer revolutions—assuming sufficient torque is available.

How Pitch Affects Engine RPM and Efficiency

-

Higher Pitch

-

Lower engine RPM at a given speed

-

Greater top-end potential

-

Increased engine load

-

-

Lower Pitch

-

Higher RPM

-

Faster hole shot

-

Reduced top-end speed

-

Because the VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992 is engineered as a rear propeller, its pitch selection is intended to complement the forward prop while refining thrust output rather than initiating it.

Dual-Prop Systems Explained

In counter-rotating dual-prop systems, two propellers rotate in opposite directions on a shared axis. As a result, torque steer is neutralized and water flow is reconditioned before exiting the gearcase.

The rear propeller performs several critical functions:

-

Straightening disturbed water flow

-

Enhancing directional stability

-

Recovering lost thrust efficiency

-

Reducing ventilation during turns

Because of this role, rear propeller geometry is optimized differently from front propellers.

Rear Propeller Pitch Strategy

Rear propellers often use equal or slightly higher pitch values to maintain propulsion harmony. When matched correctly, thrust overlap is minimized and slip is reduced. Therefore, smoother acceleration and improved cruise efficiency are achieved.

Why Compatibility Matters More Than Brand Alone

Propeller performance is not universal. Even when an OEM propeller is selected, compatibility must be evaluated holistically. Engine horsepower, gearcase ratio, hull characteristics, and operating conditions all influence whether a propeller delivers optimal results.

For this reason, the VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992 should be viewed as part of a system, not a standalone component. When matched correctly, efficiency, reliability, and handling improvements are fully realized.

How Verado Dual-Prop Systems Differ

Mercury Verado engines equipped with dual-prop gearcases utilize counter-rotating propellers mounted on concentric shafts. This configuration is engineered to:

-

Neutralize torque steer

-

Improve low-speed control

-

Increase grip in aerated water

-

Maintain stability at higher speeds

Because water flow is conditioned by the forward propeller before reaching the rear propeller, rear prop selection must account for altered hydrodynamics.

The Rear Propeller’s Role in the System

The rear propeller does not duplicate the work of the front prop. Instead, it:

-

Reclaims disturbed water flow

-

Straightens thrust vectors

-

Enhances directional control

-

Stabilizes RPM under load

As a result, rear propeller pitch and geometry are optimized differently from front propellers.

Gear Ratio Fundamentals

Gear ratio determines how many engine revolutions are required to turn the propeller once. This ratio directly affects:

-

Engine RPM

-

Propeller load

-

Acceleration characteristics

-

Cruising efficiency

Higher gear ratios allow propellers to spin faster relative to engine RPM, while lower ratios increase torque multiplication.

Matching Pitch to Gear Ratio

A 33-pitch rear propeller is typically paired with gear ratios that support efficient high-speed cruising. When matched correctly:

-

Engine RPM remains within manufacturer specifications

-

Throttle response feels linear

-

Fuel efficiency improves at cruise

However, if pitch is too high for the gear ratio, engines may struggle to reach optimal RPM. Conversely, insufficient pitch can cause over-revving.

Why Horsepower Influences Prop Selection

Higher horsepower engines generate greater torque. As torque increases, propeller blade integrity becomes increasingly important.

The stainless steel construction of the VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992 ensures that:

-

Blade flex is minimized

-

Effective pitch remains consistent

-

Thrust delivery remains predictable

Because of this, higher-horsepower Verado engines benefit most from stainless steel rear propellers at higher pitch values.

Turning Technical Design into Measurable Results

Propeller specifications matter only insofar as they deliver real results on the water. While pitch numbers and blade geometry describe engineering intent, outcomes such as cruising comfort, fuel economy, and predictable handling define ownership satisfaction.

The VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992 is engineered to convert available horsepower into controlled, efficient thrust. As a result, performance improvements are not theoretical—they are experienced.

How Rear Prop Pitch Influences Speed

In dual-prop systems, speed gains are achieved not by brute force, but by efficiency. The rear propeller refines water flow exiting the gearcase. Consequently, drag is reduced and thrust is straightened.

With a 33-pitch rear propeller:

-

Distance traveled per revolution increases

-

Engine RPM at cruising speed decreases

-

Top-end efficiency is improved

Rather than forcing the engine harder, speed is achieved through improved hydrodynamics.

Stability at Higher Speeds

As speed increases, instability becomes costly. The rear propeller mitigates this risk by smoothing thrust delivery. Therefore, steering inputs remain controlled and predictable, even as velocity rises.

Why Efficiency Improves at Cruise

Fuel efficiency is most often realized at steady cruising speeds. At these RPM ranges, higher pitch rear propellers allow engines to maintain speed with reduced throttle input.

Benefits include:

-

Lower fuel burn per mile

-

Reduced engine strain

-

Extended range on long runs

Because the propeller maintains pitch integrity under load, efficiency gains are sustained rather than intermittent.

Real-World Cruising Scenarios

For offshore runs, inter-island travel, or long coastal cruises, consistent efficiency matters more than peak speed. The 33-pitch rear configuration supports these use cases by stabilizing RPM and minimizing unnecessary drag.

Is a 33-Pitch Rear Propeller Too Aggressive?

A 33-pitch rear propeller is not inherently aggressive. Instead, it is application-specific. When paired with appropriate horsepower, gear ratios, and hull design, it enhances efficiency rather than overloading the engine. Therefore, performance gains are realized without compromising reliability.

Will This Propeller Reduce Hole Shot?

Hole shot performance is primarily influenced by the front propeller in dual-prop systems. The rear propeller refines and stabilizes thrust. As a result, acceleration characteristics remain largely unchanged while cruising efficiency improves.

Does Stainless Steel Increase Wear on the Gearcase?

When OEM-matched, stainless steel propellers reduce wear, not increase it. Because blade flex is minimized, slip is reduced. Consequently, RPM stability improves and drivetrain stress is lowered over time.

Can This Propeller Improve Fuel Economy?

Yes—particularly at cruising speeds. Higher pitch rear propellers allow engines to maintain speed at lower RPM. As a result, fuel burn per mile is often reduced during sustained operation.

Is This Propeller Suitable for Rough Water?

Yes. The rear propeller conditions disturbed water flow, which improves grip and reduces ventilation. Therefore, handling remains predictable even in aerated or choppy conditions.

OEM vs Aftermarket Rear Propellers

Why OEM Matters in Dual-Prop Systems

Dual-prop systems require precise balance. OEM propellers are engineered alongside the engines they support, ensuring:

-

Verified load calculations

-

Consistent metallurgy

-

Controlled balance tolerances

-

Predictable RPM behavior

Aftermarket alternatives may fit physically; however, hydrodynamic and structural differences often introduce variability.

Cost Comparison Over Time

Although aftermarket propellers may carry a lower upfront price, long-term costs often increase due to:

-

Reduced efficiency

-

Increased replacement frequency

-

Potential drivetrain wear

OEM stainless steel propellers typically deliver lower total cost of ownership.

33-Pitch vs Lower Pitch Rear Propellers

When 33-Pitch Is the Better Choice

This configuration excels when:

-

Cruising efficiency is prioritized

-

Loads are consistent

-

Engines comfortably reach recommended RPM ranges

-

Top-end performance feels limited by propeller efficiency

When Lower Pitch May Be Preferred

Lower pitch rear propellers may be considered when:

-

Boats are heavily loaded

-

Operating environments demand rapid acceleration

-

Engines struggle to reach target RPM

Pitch selection should always reflect real-world usage rather than theoretical performance.

Installation, Setup, and Post-Install Checklist

Installation Best Practices

To ensure optimal performance:

-

Use manufacturer-recommended thrust washers

-

Apply correct torque values

-

Confirm clean spline engagement

-

Inspect for free rotation after installation

Correct installation preserves balance and prevents premature wear.

Post-Installation Verification

After installation:

-

Verify engine RPM at wide-open throttle

-

Observe handling characteristics

-

Monitor fuel efficiency at cruise

-

Listen for abnormal vibration

These checks confirm that the propeller is operating within intended parameters.

Troubleshooting Common Concerns

Engine Cannot Reach Recommended RPM

This may indicate excessive pitch for the current setup. Load reduction or pitch adjustment may be required.

Vibration After Installation

Vibration is typically caused by improper installation, damaged hardware, or debris. OEM propellers themselves are factory-balanced.

No Noticeable Performance Change

Performance differences are most apparent during cruising and sustained operation. Short test runs may not fully reflect benefits.

Buyer Confidence Summary

Choosing the correct rear propeller is about alignment, not experimentation. When matched appropriately, the VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992 delivers:

-

Refined thrust output

-

Improved cruising efficiency

-

Stable, predictable handling

-

Long-term durability

-

OEM-backed reliability

This propeller is not designed for compromise—it is engineered for precision.

Why Propeller Choice Is a Safety Decision—Not Just a Performance One

Safety on the water is not governed solely by operator skill or engine power. Instead, it is shaped by how predictably a vessel responds to steering input, throttle changes, and environmental conditions. The rear propeller plays a decisive role in this equation.

The VERADO12 33 PITCH MERCURY RH 3 BLADE REAR PROPELLER 48-8M0166992 has been engineered to support controlled propulsion delivery, particularly in situations where stability and responsiveness directly impact safety outcomes.

Controlled Thrust Equals Predictable Steering

At higher speeds, even minor steering corrections can translate into significant directional changes. When thrust exits the gearcase unevenly, steering input can feel delayed or exaggerated.MERCURY RH 3 BLADE

Because the rear propeller straightens and refines water flow, thrust vectors remain aligned with the vessel’s centerline. As a result:

-

Tracking remains straight

-

Steering corrections feel proportional

-

Sudden yaw is minimized

This predictability is critical when operating in open water, near traffic, or in changing sea states.

Counter-Rotation for Balance

Torque steer places constant corrective demand on the operator. Over time, this leads to fatigue and reduced situational awareness.MERCURY RH 3 BLADE

In dual-prop systems, the rear propeller counteracts rotational forces generated by the front propeller. Consequently:

-

Steering effort is reduced

-

Helm input remains neutral

-

Long-distance operation becomes less taxing

By reducing physical strain, control is maintained for longer periods—an often overlooked safety benefit.

Maintaining Grip When Conditions Degrade

Rough water introduces aeration, which can disrupt propeller bite and lead to ventilation. Loss of grip at speed compromises control.MERCURY RH 3 BLADE

The rear propeller’s blade geometry is optimized to re-capture disturbed water flow. Therefore:

-

Thrust consistency is preserved

-

Sudden RPM spikes are reduced

-

Steering authority is maintained

This stability is especially valuable when crossing wakes, navigating chop, or operating offshore.

Controlled Reverse and Maneuvering

Safety risks are not limited to high-speed operation. Docking, reversing, and tight maneuvering often occur in close proximity to people, structures, and other vessels.

Because thrust is refined as it exits the gearcase:

-

Reverse engagement feels smoother

-

Lateral drift is reduced

-

Fine throttle adjustments are more effective

This precision supports safer marina operation and reduces the likelihood of accidental contact.

Predictable Response Under Sudden Input

Emergency avoidance requires immediate and predictable response to throttle and steering commands. Any delay or instability increases risk.VERADO12 33 PITCH MERCURY RH 3 BLADE

A properly matched rear propeller ensures that:

-

Throttle response remains linear

-

Steering input produces consistent results

-

The vessel maintains composure during abrupt maneuvers

In critical moments, predictability is a safety feature.

Reduced Vibration and Component Stress

Mechanical instability can translate into control issues. Excess vibration affects steering feedback and can mask early warning signs of failure.VERADO12 33 PITCH MERCURY RH 3 BLADE

OEM-balanced stainless steel construction ensures:

-

Smooth rotational dynamics

-

Reduced gearcase stress

-

Consistent helm feedback

By preserving mechanical integrity, operational safety is indirectly reinforced.

Choosing a rear propeller is often framed as a performance upgrade. However, safety and control outcomes are equally important.

This configuration supports operators who value:

-

Confident handling at speed

-

Reduced fatigue during long runs

-

Stable behavior in unpredictable conditions

-

Precision control in confined spaces

When safety margins matter, component selection becomes strategic.VERADO12 33 PITCH MERCURY RH 3 BLADE

Reviews

There are no reviews yet.